Belt Drives

Types of Belts

Flat Belts

Simple rectangular cross-section

One or both sides can be specially coated to increase friction with pulleys

Pulley is slightly convex to keep the belt centered on the pulley and prevent it from falling off

~98% efficiency

High flexibility (can be used effectively with small pulleys)

High pretensioning forces/bearing load

- Use outer diameter of the pulleys to calculate transmission ratio

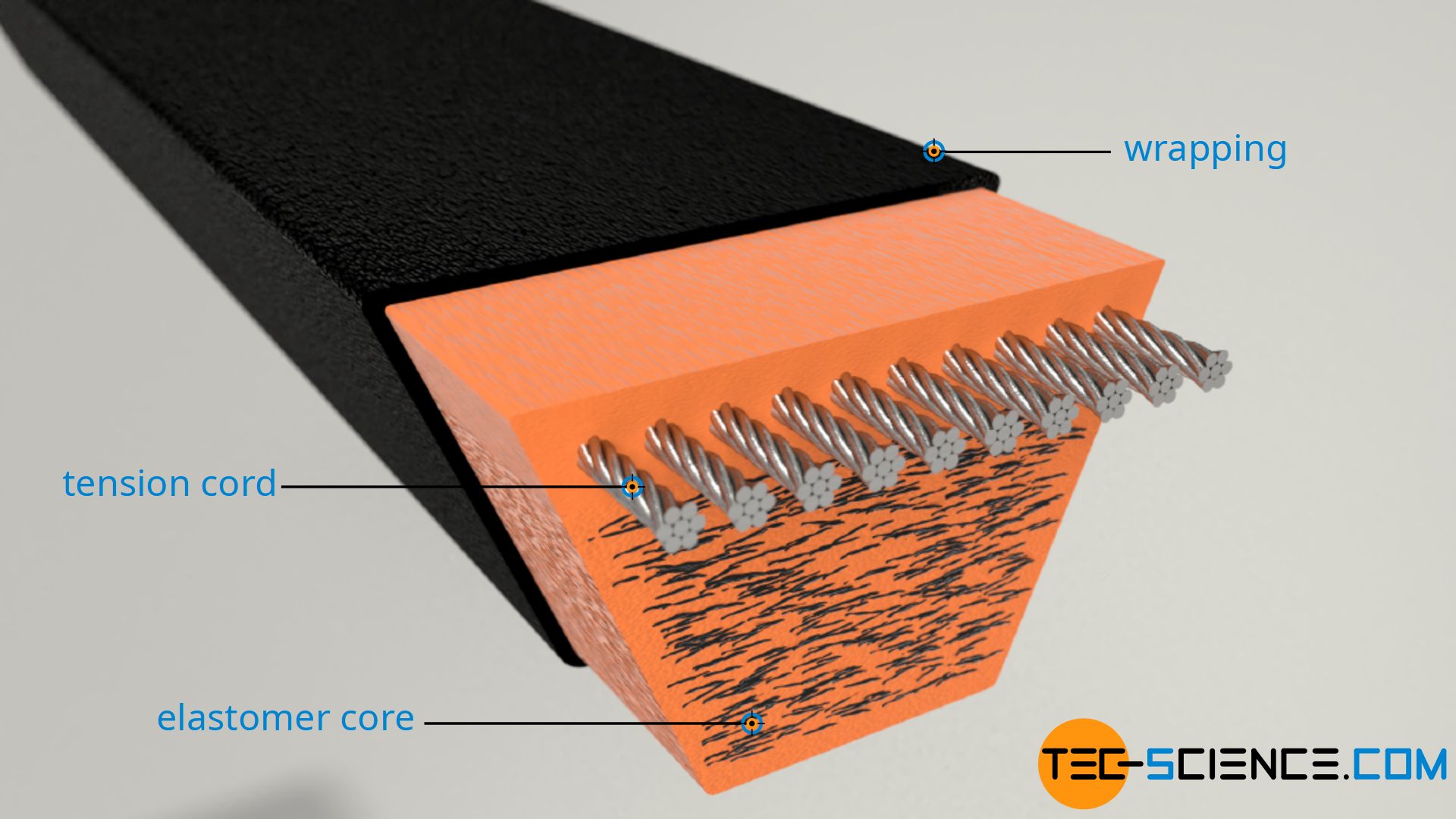

V-Belts

Reduced bearing load

Wedge-shaped cross section

- Higher friction than flat belts due to wedge shape

- Higher torques can be transmitted with the same pretensioning force

- Two+ belts can be placed parallel to each other to increase power transmission as well

- Belt only contacts the pulley on the inclined flanks (does not touch the bottom of the groove)

- Groove angle of 38° or 32° depending on pulley diameter

- Each belt is specially designed for a certain range of pulley diameters

- Different way of calculating transmission ratio (nominal width/neutral axis)

| Type of V-Belt | Description |

|---|---|

| Classical |

|

| Narrow |

|

| Wide (a.k.a. variable speed) |

|

| Double (a.k.a hex) |

|

| Kraftband |

|

| Coating Type | Description |

|---|---|

| Wrapped |

|

| Raw |

|

Timing/Synchronous Belts

- Toothed to eliminate slippage

- Used when precise positioning is required

- Higher power density (can use smaller belts and pulleys for a bigger load)

- More expensive

- Require less tension (and cause less wear)

Round Belts

- Round cross section

- Used more for motion transmission than power transmission

Chains

- Longer length

- Better in high temperatures

- Needs lubrication and more maintenance

Timing Belt Specifics

The list above is an introduction I guess, but really we want to be using timing belts. Any other type of belt doesn't have teeth and relies only on friction, causing it to slip occasionally, which is bad for our purposes.

Tooth Profiles

Note: Belts with the same type of tooth profile and pitch may not be interchangeable, due to differences in manufacturer's designs

| Type | Description | Pros | Cons | Picture |

|---|---|---|---|---|

| Trapezoidal |

|

|

| |

| Curvilinear |

|

|

| |

| Modified Curvilinear |

|

|

|

Pulley Mounting

| Type | Details |

|---|---|

| Set screws |

|

| Split hub |

|

| Quick disconnect bushing |

|

Taper lock (a.k.a keyless bushing) |

|

Theory

https://www.thomasnet.com/pdf.php?prid=101106

| Concept | Symbol | Definition |

|---|---|---|

| Belt pitch | p | The distance between the centerlines of two adjacent teeth |

| Belt pitch line | The centerline of the cords inside the belt (near the top) | |

| Pulley pitch | The arc length between the centerlines of two adjacent pulley grooves | |

| Pitch circle | The pitch line of the belt when wrapped around the pulley. In timing belts, the pitch diameter is larger than the pulley outside diameter. | |

| Pitch diameter | d | The diameter of the pitch circle |

| Pulley outside diameter | The diameter measured from the ends of the teeth | |

| Belt length | L | If zb = number of teeth, L = p⋅zb |

| Concept | Symbol | Calculation | Definition |

|---|---|---|---|

| Centre distance | C | The distance between the centers of the two pulleys. | |