Material Choices

Ethan Cronier

Austin Tailon Huang (Deactivated)

Look at this carbon fiber arm!

Aluminum Alloys

All property information taken from relevant pages on MatWeb.

Typical Density: 2700kg/m^3

Typical Modulus of Elasticity: 70.0 GPa

Typical Yield Strength By Alloy Series:

- 3000 Series: 29 - 285 MPa

- 5000 Series: 40 - 540 MPa

- 6000 Series: 40 - 517 MPa

- 7000 Series: 69 - 730 MPa

Alloy Series

Most types of aluminum are named with a 4 digit number, followed by a letter and a number (i.e. 6061-T6 aluminum). The four digit number is wrought alloy designation system, and the letter and number is the temper designation. The most signification number to look at is the first number, which represents a different principal alloying element.

Notes on Each Alloy Type

Although there are a ton of types of aluminum alloys you can get, the most commonly used alloys are 3003, 5052, 6061 and 7075 aluminum alloys. Each of these alloy types are suited towards different applications.

- 3003: Highly workable, corrosion resistant, easy to anodize and laminating.

- 5052: Similar to 3003, but better strength and corrosion resistance. Very common material used for folding applications

- 6061: Most versatile and widely used alloy. Heat treatable, easy to weld, easy to machine, highly corrosion resistant, medium strength. Very common material to use for CNC'd aluminum parts

- 7075: Highest strength aluminum alloy within this list, not weldable.

| Pros | Cons |

|---|---|

| ~2.5 less dense than steel, so aluminum is much lighter | ~ 3x the price of steel (but still pretty economical in the grand scheme of things) |

| Very easy to custom machine, and is suitable to a lot of fabrication process such as folding, welding and CNC machining | ~ More susceptible to failure than steel |

| Can be anodized with colors to add aesthetic flair to the rover | Most hardwares are made of alloy steel, so aluminum mated with steel fasteners MAY result in contact corrosion |

| Good corrosion resistant | Very electrically conductive, so we can run into shorting problems if we aren't careful (that would never happen tho right |

| Recyclable |

On Campus Availability

5052 and 6061 aluminum alloys can be purchased on campus at the ESMS, so we have very high accessibility for these materials directly on campus. We also have some stock material for these types of material scattered in the bay, but it's gonna be a mission and a half to sift through all that crap. Aluminum alloys can also easily be machined and fabricated with the SDC facilities on campus, so it's very easy to make these parts in house if we have the materials!

Sponsorships

We also have two machining sponsors that will fabricate aluminum parts for us for FREE! Wyrks Tool and Machine Ltd and Demtool both provide machining services for this type of alloy (folding, welding, laser cutting, CNC machining, you name it!) which also includes the stock material, provided they have it on hand and you aren't used some wonky alloy.

Aluminum is DEFINITELY a material we should use for our new arm design. It's a great material custom machine our parts with as it's both light, strong, easy to manufacture and highly accessible. This is pretty much a no brainer.

Carbon Fiber

The physical properties of a piece of stock piece of carbon fiber is heavily dependent on the supplier of the material. To get accurate values of physical properties, its best to contact the vendor to see what's going on. The properties listed below are general ranges taken from MatWeb, but they are super wide. Comparisons of carbon composites with aluminum from specific vendors will be discussed later.

Typical Density: 1150 - 2250 kg/m^3

Typical Modulus of Elasticity: 2.62 - 520 GPa

Typical Yield Strength: 4.62 - 3220 MPa

Forms of Carbon Fiber

Typically, carbon fiber can be purchased in sheets, panels and tube forms. All types of carbon fiber parts materials are generally constructed under the same kind of concept: carbon fiber weave is coated and cured in high strength epoxy to maintain shape and form. Overall, carbon fiber is a very strong and lightweight material that makes it great to select for structural components.

Carbon fiber tubing is a very viable material option we can use for our rover. Carbon fiber tubing is a finished sold product that we can cut and modify to use in the structural members of our arm. To my current research, two main types of carbon fiber tubing- unidirectional and multidirectional. Unidirectional carbon fiber tubing comes has all fibers aligned in the same direction, and is typically pultruded or wound. Pultruded carbon fiber tubing uses lengthwise oriented fibers, and is strong in bending/tension but weak in compression/torque. On the flip side, wound carbon fiber tubing is wrapped around the tube and is strong in torque/compression but weak in tension/bending. On the other hand, multidirectional carbon fiber tubing includes a weave, and is relatively consistent in all force applications. These typically come in braid and roll wrapped form. Unidirectional carbon fiber tubing is typically cheaper than multidirectional, so if you can get away with a unidirectional tube you can save some money ![]() . Note: You can also get carbon fiber box tube!

. Note: You can also get carbon fiber box tube!

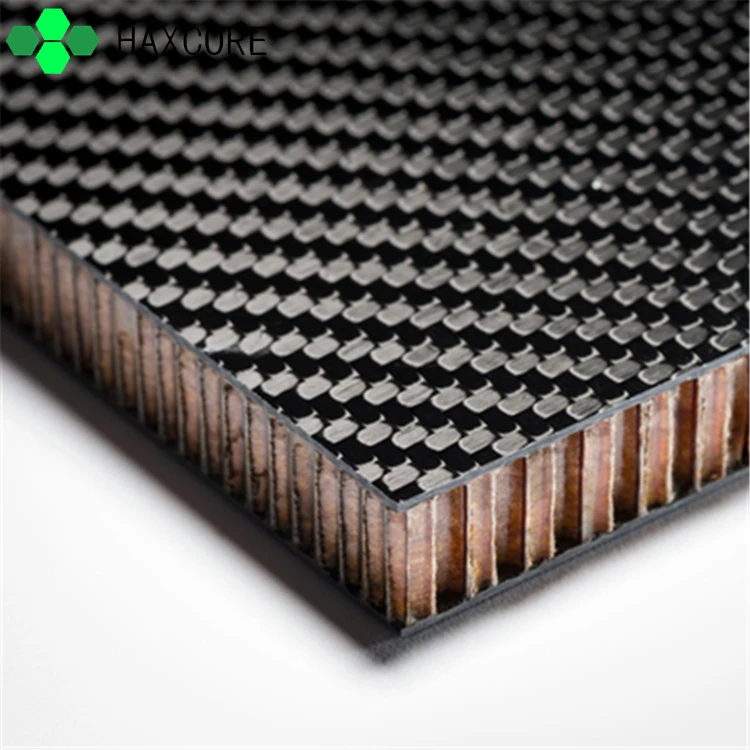

Carbon fiber sheets are flat pieces of carbon fiber weave that come either cured or uncured. When cured, they are rigid sheets that you can cut into shapes (like flat metal stock for laser cutting, although you can't laser cut carbon composites cuz it will melt the epoxy). Uncured sheets aren't rigid as they don't have a higher amount of epoxy, and you can use to form and cure custom surfaced carbon fiber parts. Carbon fiber panels are flat pieces of carbon fiber that typically use some honeycomb weave pattern in the middle of it's thickness, and is used as you would expect- as a panel lol.

Cutting/Machining Carbon Fiber

There's a lot of shit to consider when trying to cut or machine carbon fiber parts. First, is carbon dust. Whenever you cut carbon fiber parts, you generate small particles of carbon dust which are an irritant to the skin AND lungs. When cutting or machining carbon fiber, you should always make sure that you are in a well ventilated area, and you are wearing good eye and respiratory PPE to avoid getting irritant in your mouth and eyes. A really good practice to employ when cutting is to have some sort of shop vac or ventilation running near by to suck up all the dust particles you produce. Here's a good video showing what practices to use when cutting carbon fiber:

Another thing to consider is your actually machining tools. If we are machining carbon fiber tubes, we will probably only be looking into cutting and drilling applications, so that's all I've researched for the moment. Carbon fiber is a very hard material, so whether you are drilling or cutting you want to make sure you are using a sturdy and hard fabrication material that won't wear down when cutting carbon fiber. You can cut carbon fiber with a dremel, but you probably want a diamond coated cutting wheel that won't die and wear out. Same things goes for drilling applications, at minimum you probably want a carbide or diamond tipped drill bit that won't die. If you are careful, you can hand drill carbon fiber tubing!

There are a couple of other specifics to consider when machining carbon fiber tubing. It's important to take your time when cutting and drilling, and to really go slow and not rush things. When you cut things fast, you can delaminate unidirectional tubing which damages the carbon fiber filaments. Also, if you rush things you can run the risk of melting the epoxy that's holding the carbon fiber tubing together if you cut too fast. You can also use coolant to fix that though. After you cut, you will likely need to sand down the end of the tube to give it a proper finish, as its hard to get a completely clean cut.

Carbon Fiber Vs. Aluminum

I wanted to include a section on carbon fiber vs aluminum, just to provide some specifics as to why carbon fiber would be a superior material to aluminum for structural components for arm linkages. This information is taken from dragonplate, a carbon fiber composite manufacturer.

Carbon fiber is much stronger than aluminum and less dense, so we can use smaller carbon fiber parts to achieve the same strength as aluminum at much lower weights! This is great for our arm, as with lighter linkages we can reduce overall arm weight, and further optimize the center of mass for our arm - we have more flexibility for linkage design. One thing to consider however is that carbon fiber is much less flexible that aluminum, so it won't show signs of yielding before it completely breaks and fails. That being said, it's strong AF and we aren't designing a robot with a 10 year life span, so if we engineering things correctly the change of that happening is super low.

Considerations when Using Carbon Fiber Parts

Carbon fiber does not react favorably with aluminum in the galvanic series. In fact, when you put carbon fiber in contact with aluminum, there is a very severe galvanic reaction that can occur between them in presence of an electrolyte. Now, this may not be a big issue for our design/service cycle, but typically in industry direct electrical contact between aluminum and carbon fiber is avoided! This can be mitigated by introducing insulating mediums. Powder coated aluminum probably won't face too many issues with contact corrosion if done correctly. If we are mating carbon fiber and aluminum together on flat or simple surfaces, we can also consider designing very thin 3D printed shims to use insulating plastic to isolate the aluminum and carbon fiber. You can also paint the carbon fiber to insulate the two surfaces! Fiberglass layers are also commonly be used to insulate aluminum. We can also use titanium instead of aluminum but bruh. expensive.

Also, if you need to fasten nuts and bolts into a carbon fiber sheet, stainless steel is a good recommendation over alloy steel due to the lower difference in potential.

| Pros | Cons |

|---|---|

| Lighter and stronger than aluminum! | Isn't super workable.. you can cut and drill into it easily but can't CNC or laser cut complicated parts |

| Really cool visual aesthetic for braided parts | Need to wear PPE to avoid dust particles when machining |

| More design flexibility/Center of mass optimization available | May need extra design considerations for galvanic reaction between aluminum and carbon fiber |

| Comes in tube form which is easy to design linkages with | More expensive than aluminum |

| Good for surfacing |

Composites Canada: I've contacted these guys to set up a sponsorship. Still waiting to hear back, will probably send a follow up email soon.

Rockwest Composites: This is a huge carbon fiber company, and they offer 15% off all purchases to student design teams

In theory this would be a great material for making structural members on the arm. I think carbon fiber tubing presents a very simple solution that is easy to work with, that we can connect to custom machined aluminum parts at the joints as long as we take proper precautions to isolate the two materials

Steel

Properties

typical density: 8050 kg/m^3

typical yield strength (CRS): 580 Mpa

Other info

Cheap, everyone has it

pastics:

- 3dprinted plastic

- UHMW plastic

- delerin

- nylatron

- PTFE

- Urethane rubbers (for gripper)

- Silicon (for gripper)

- Carbon fiber

- Fiberglass