WHEEL RESEARCH

Considerations:

- OTS : no custom hubs, cheaper, faster for prototyping

- Timeline/prototyping

- Accuracy to what can be used on an actual Mars mission

- Weight

- Price point

- Customizability/design uniqueness

- What has been successful for other teams

- Size (less than 16”, greater than 10”) for 6 wheel drivetrain

- maintenance

- coefficient of friction

- maximum load

- width/tire thickness

- Internal diameter (ID)

Main Solutions (In depth)

| Consideration/Topic | Entirely 3D Printed Wheels | beach tires with 3D printed treads | Solid Tread, flat free wheels |

|---|

| general/description | - self explanatory, design entire wheel

| - design various attachable 3D printed tread patterns to the beach tires

| - most basic option

- used as is

|

Timeline/prototyping | - may take many weeks to create from designing, sourcing filament, printing, prototyping to final product

| - can reliably test far faster - begin testing with just the beach tires and can add treads later

| - would need to alter hub to accommodate motor

|

| Educational aspect | - improve design skills

- opportunity to analyze various tread styles for the terrain

- analyze possible spoke styles/internal support for weight of rover as well deformability

- create/implement custom hubs

| - opportunity to analyze various tread styles for the terrain

- figure out a way to firmly attach treads to wheel

- Stanford - zip ties (prototyping)

- Cornell (2020)-adhesives -cyanoacrylates, epoxy?

| |

Accuracy to what can be used on an actual Mars mission | - airless tires would be more accurate to what is possible on Mars missions

| n/a | |

| Size options | entirely customizable (between 10" -15") | Wheeleez: - diameter: 9.4" width:

- diameter: 11.8" width: 7.3"

- diameter: 16.5" width:

McMaster Carr - 8"

- diameter 10" width: 1 5/8"

| |

| Weight | unsure, but would likely be heavier as it is made of solid material | WheelEEZ: 11.8" : 1.3 kg (2.9 lbs)

McMaster-Carr 10": couldn't find | n/a |

| Price point | n/a | 11.8": $89.00

10": $85.58 | $75-160 13": $124.43 |

Customizability/design uniqueness | - entirely custom allowing for custom wheel hubs and any spoke/tread design we may want

- would have the ability to expand on this for future years

| - tire is OTS but treads would/could be custom made and this would also allow us to prepare for a more advanced wheel design for a future rover

- possibility of a custom hub (hub that comes with wheels is completely removable

| |

| maintenance | - cannot be fully sure until prototyped

- design could be less resistant to catching sand, wearing down etc.

| - unlikely, but sand could enter hubs/bearings - should choose a reliable design (Wheeleez has multiple parts such that the entire hub can be easily taken apart and cleaned/repaired/replaced)

- cuts can be repaired using a soldering iron

- possibility for 3D printing different interchangeable attachable treads to have better treads prepared for competition/less worn down/new treads

|

|

Coefficient of friction | 0.38 (for hole wheel design)* 0.45 (for spike wheel design)* | WheelEEZ: 0.2-0.25 (website did not have specific values, against steel) McMaster-Carr: n/a | n/a |

Maximum load | n/a | WheelEEZ: 55kg McMaster-Carr: 1.2kg | 0.3kg |

Other teams | | | n/a |

| OTS Options/purchase options | filament here Thermoplastic Polyurethane TPU (AGH Space Systems, ITU) Polyethylene terephthalate glycol PETG (ITU) black SemiFlex clear generic TPE90A white NinjaFlex (very soft, therefore harder to print)

| | McMaster-Carr https://www.mcmaster.com/22245T33/ https://www.mcmaster.com/rubber-tread-wheels/ |

| Example photos | Monash:

ITU:

| WheelEEZ wheel:

Cornell:

hub:

Custom hub (cornell):

| |

Materials:

| Material type | | Coefficient of Friction μ | Benefits | Drawbacks | Other Notes |

|---|

| Air Tires | beach tires |

| - can purchase commercially

- cost is under $100

| - have to design within constraints of COTS wheel hubs

| - similarly to Stanford, nylon chains and grips can be added to the surface of the wheels for more traction

- 8-12" diameter for a 6 wheel design (from old research

- can adapt

- Can adapt to a 6” diameter hub motor

- Width exceeding 4” (by experience, can analyze for more detail, too narrow tires can significantly increase ground pressure)

- Any 2 tires in design must be able to handle entire rover load without rupturing

|

| Rubber | ATV sand tires |

| - tried and tested to be efficient in sand dunes

| - would have to emulate the design ourselves/cannot buy commercially because regular ATV sand tires are too big

| - can change pressure within tires, when tires are deflated to 10-20 psi, better for sandy terrain

|

cast with molds | 0.9 (on asphalt) | - customizable

- can use with custom hubs

| - prototyping time that could be spent working elsewhere

- need to learn how to use molds and casting

| - refer to Ryerson Rams design

|

| Metal | Aluminum (curiosity rover) | 1.10-1.35 (on aluminum) | - more similar to current tech used on Mars (air tires cannot be used due to Mars' atmosphere)

| - depending on thickness of wheel/design, similarly to Curiosity Rover, the aluminum wheels could experience some damage

|

|

Titanium nickel alloy (webbed material used for bike tires created by The SMART Tire company) |

| - has been approved by NASA

- would be more suitable for real Mars conditions

| - difficult and expensive to imitate

- deformations can occur if shape memory alloys are not used

| https://www.syfy.com/syfywire/nasa-space-tires-never-go-flat-coming-to-your-bicycle |

|

3D Printed (use thermoplastic elastomers) | white NinjaFlex (very soft, therefore harder to print) | 0.69 (for smooth wheel design)* | - customizability

- compliant wheel internal design (with soft thermoplastics)

- Can rapidly prototype various wheel designs

- custom hubs can be used which is easier for mounting motors on wheels

- With custom hub design as well, possibility of swapping tires

- FEA justified

| - printing/prototyping time that could be spent working elsewhere

- less reliable than commercially designed tires

| *referenced this report which used small scale wheels https://www.sciencedirect.com/science/article/pii/S2212827117300793 (μ measured on aluminum) - another material option is elastomer latex, but that is not commercially available

|

clear generic TPE90A | 0.45 (for spike wheel design)* |

black SemiFlex | 0.38 (for hole wheel design)* |

Interesting Tire Shapes (treads and spokes?)

| Tire Shape Name | Photos | Extra notes |

|---|

| Humvee Airless Tire | | - in prototype stage for (U.S.) Army Research Lab by Resilient Technologies

- made of polymers

- benefit: would be more accurate to tech that can actually work on Mars

- drawback: have to ensure that nothing can get stuck within spokes

|

| Michelin UPTIS airless tire | | - demo clips of it rolling over a nail and continuing

- no need to check air pressure

- cast a design like this or 3d print (with soft thermoplastics) a design like this?

- benefit: would be more accurate to tech that can actually work on Mars

- drawback: have to ensure that nothing can get stuck within spokes

|

| Loopwheel | | - a bike tire design, but the "spokes" are interesting bc they have been designed to readjust and therefore change the shape of the tires for rougher terrain

|

| Sand tires | | - specialized ATV/UTV

- rear tires: paddle like ridging to dig into sand

- front tires: completely smooth, few ridges for steering purposes, ridges raised along the center allow for bite to make more immediate turns-might not be good to implement these bc the rover won't be going as fast (don't need to glide).

|

| SMART Tires | | - bicycle tire design

- still in prototyping phase-final product is planned to be encased in rubber & polyurethane

|

Wheel designs from other teams:

| Team Name | Year and Info | Pictures |

|---|

| IMPULS: | 2021: 300 mm wheels, wheels have not changed from 2019 design (as far as I can see). Their spokes and frame seem to be custom made (machined and acrylic?) | |

| Ryerson Rams: | Previously (before 2019) used rigid wheels, too much force into suspension, not enough traction (stated in video)

2019: Prototyped highly deformable wheels, flexible 3d printing, casting rubber tires - final design seems to be casted rubber tires. | |

| 2021: 3D printed PETG hubs and casted polyurethane treads for flexibility, shock absorption, traction | |

| Stanford | 2019: included nylon chains, inflated wheels | |

| 2020: Wheels are still inflated, more traction(not explained in SAR) but it seems a (rubber?) textured piece has been attached to the outer surface of the wheel

Small clip in SAR shows one wheel with a different surface? (side note they mentioned a “Grass hopper suspension”, distributes weight away from lowest handing wheel to glide/avoid obstacles/handle rocky terrain) | |

| PCz: | 2021: 3d printed 14 inch wheels for shock absorption and traction. Their design has similarities with the Curiosity rover’s treads: | |

| Monash (9th place): | 2019: beach tires | |

| 2021: 3D printed wheels, individually driven- frame and treads are all 3d printed. | |

Research from NASA's rovers:

Nasa’s perseverance rover has wheels made of aluminum, cleats for traction curved titanium spokes for springy support. (20.7” diameter)

Change in wheels from curiosity to perseverance:

Curiosity began experiencing wear along the treads (6.4 mm thick) of the tires faster than expected. Furthermore, the aluminum tires of curiosity were milled to 0.75 millimeters thick which was thin enough to easily experience damage along sharper terrain.

Spring Tire Design from Goodyear:

Uses shape memory alloys which allow it to deform and then return to its original shape. This design is likely unattainable for our rover due to the special material it uses, but it is still an interesting design.

NASA Spring Tire Design:

Main conclusion (for now): many high level teams switched from inflated tires to 3D printed tires for their customizability and (seemingly) to emulate more of NASA's designs.

Tread Adhesives (for prototyping/removable)

| Adhesive name | Description | Cost | Image |

|---|

| Silicone Sealant/glue | - can be used for glass, metals, plastics

- water resistant, flexible

- can be removed with exacto knife and acetone (for excess remaining)

- any cuts made by exacto knife on wheel can be fixed with soldering iron

- equipment: caulking gun

| ~$20 for 11oz container | |

| APAO Based hot melts | - non crystalline adhesives that stay flexible and tacky

- good adhesion

- long open times

- can be used for woodworking, automotive assembly

- remove with rubbing alcohol, hot gun, scraper

- equipment: hot melt gun (glorified glue gun)

| | |

| rubber cement | - can be removed with heat and force: heat gun and scraping

- good long term option, used for outdoors (bike tire repairs)

- acetone can be used to remove any excess remaining

- note: acetone supposedly beads up on/does not affect polyurethane

- equipment: brush for application

- does suggest scuffing up the area first for better adhesion

| ~$9 for 8oz container

mcmaster carr: plastic cement https://www.mcmaster.com/adhesives/for-use-on~polyurethane-rubber/cement-for-plastic/ | |

| other testing option | - stanford used zip ties to attach the treads to their wheels

- would only use for prototyping

|

|

|

Tread Styles

| Style Name | Photo | Notes |

|---|

| | - thick groove patterns, wear down evenly over time

|

| Asymmetric | | - move in a single direction, most common type of tire tread

|

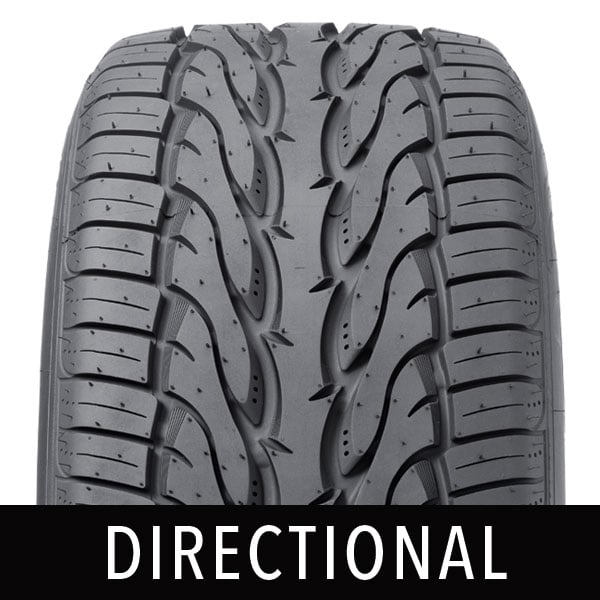

| Directional (also called unidirectional) | | - highest level of traction, control

- designed to roll in only one direction

|

| | - highest SAR Score

- scored well in 2019 competition

- greatest diameter along center of wheel

- angled ridges/small paddles

|

| PCz - zig zag pattern | | - 4th place for SAR

- video shows strong traction on snow

- contact about material type?

|

| | - additional rubber (??) strips added, horizontal lines

- 10th place SAR

|

| Anveshak | | - 8th place SAR

- horizontal ridges

|

| ATV sand tires | | - paddle like ridging to dig into sand

- generally smoother than traditional (car) tires

- printing time may be very long

- bc they stick out more, they could be harder to attach/could fall off

|

| | - reduced weight

- maintains turning ability

- printing time may be very long

- bc they stick out more, they could be harder to attach/could fall off

|

note: some teams that just used balloon tires as they are: Manipal, Rudra

POSSIBLE PROTOTYPING MATERIALS:

Rubber sheets from Mcmaster-Carr:

width: 1/2"-1"

Polyurethane sheets:

Black sheets, (dimensions for prices: 6"x6", 12"x12", 12"x24"), hardness level likely 60A (treads are usually 70A for a regular tire)

features: used for outdoors, high tension applications, high wear

cut to length option also available, but far more expensive.

Neoprene rubber sheets:

black sheets, also used for outdoors, oil and abrasion resistant, shock absorbing. Same dimensions as above.

Tread Styles to use:

Current treads:

notes: possibly have treads stick out slightly less/more paddle like (triangular profile vs square)

Rough sketch of hub design