/

Turning Considerations

Turning Considerations

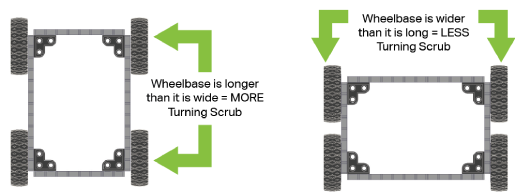

- "Turning scrub" refers to the friction that resists turning on a robot's drivetrain. This occurs from the wheels experiencing drag laterally as the robot completes its turn

- Turning scrub can be reduced by reducing the length of the drivetrain/chassis, The more length, the more sideways movement is required to turn, thus increasing scrub

- Slipping occurs when the wheel does not have a good grip on the terrain

- This can be avoided by using a suspension system – such that the drivetrain and wheel conforms to the terrain shape – and by having a high sprung mass to unsprung mass ratio

- Even better is to use a suspension system that is actively pushing the wheels into the ground, such as designs using springs

- Wheel tread design is also crucial for providing grip to a wheel's surface such that it can catch on the edges of objects

- Stalling occurs when the drivetrain is unable to overcome the turning scrub it experiences

- This means the gearing on the drivetrain motors is too low, as it is not producing enough torque

- Stalling can be avoided by calculating the required torque for overcoming the highest scrub event (i.e. when performing a one-sided turn)

, multiple selections available,

Related content

Bearings

Bearings

More like this

R&D: Research methods of creating & testing custom wheels

R&D: Research methods of creating & testing custom wheels

More like this

2021-09-30 Meeting Minutes - Drivetrain

2021-09-30 Meeting Minutes - Drivetrain

More like this

Flexible Drivetrain Design

Flexible Drivetrain Design

More like this

Drivetrain and Chassis (2021-2022)

Drivetrain and Chassis (2021-2022)

More like this

R&D: Re-design Wheel Assembly Joint for Additional Motor Mounting

R&D: Re-design Wheel Assembly Joint for Additional Motor Mounting

More like this