Bandsaw

Horizontal Bandsaw

Horizontal bandsaws is a stationary cutting device with a continuous blade driven by an electric motor in a single direction. When operating a horizontal bandsaw, the blade pivots and cuts into one end along a horizontal path with the assist of gravity[ ]. Horizontal bandsaws provide extreme precision and is good at making rough cuts to reduce material size.

Horizontal Bandsaws are [1]:

- Versatile. Capable of handling different materials such as wood, metal or plastic.

- Can operate automatically

- Quiet during operation

However, their disadvantage includes [1]:

- Unable of making angled or complex cuts.

- Stationary and large in size.

Before operating, ensure to install the correct blade depending on different types of material according to manufacturer's guidelines. Horizontal uses standard bandsaw blade sizing and should cut to the outside of the scribing to avoid cutting off too much material. In addition, the operator must ensure that the material is fixed ether though a vice or other viable means. When processing objects with excessive length such as tubes, ensure the part extended outside of the cutting table is stabilized.

A horizontal bandsaw [4] |

|---|

Vertical Bandsaw

Vertical Bandsaws ,also known as contour saws are stationary devices with the application of cutting materials into sections. A vertical bandsaw have a blade continuous driven by an electric motor in one direction which allows the user to constantly feeding the piece across it. It can also be used to cut off small amount of extra materials before polishing.

Vertical Bandsaws have the following advantages [1]:

- Cutting complex shapes and angles

- Can also be used for welding

It is however [1]:

- Stationary

- Low precision

Vertical bandsaws are generally used in small workshop that does not have large production requirements. Due to its design, operator needs to feed the piece into the blade which could be dangerous. It is advised to use the assistance of push stick although doing so might reduce precision. When cutting with vertical bandsaws, it is suggested to cut on the outer edge of the scribe mark to prevent cutting too much material off.

A vertical bandsaw [4] |

|---|

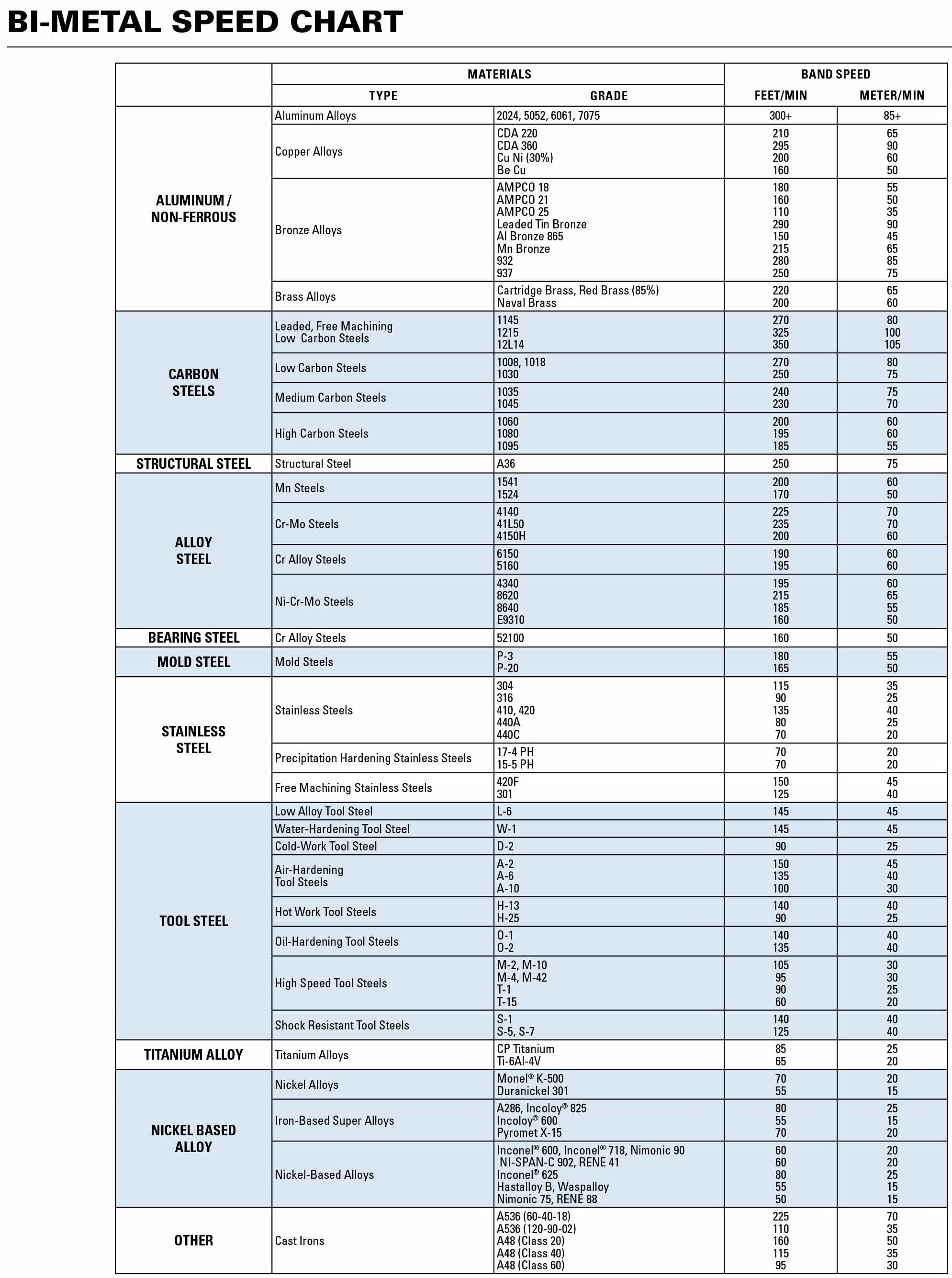

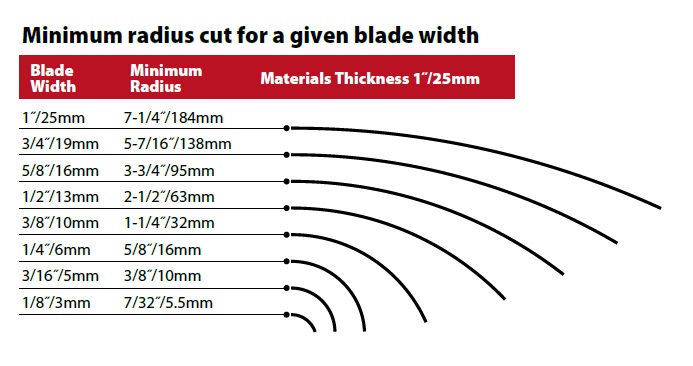

Selecting Blade Type and Cutting Speed

When operating bandsaws, it is important to select the right blade and set up the correct cutting speed according to the type of material that is going to be machined. Below are some references for setting bandsaw properly for various materials.A speed chart for cutting metals [2] |

|---|

Minimum radius cut for a given blade width [2] |

|---|

TPI for cutting metal [3] |

|---|

TPI for cutting wood [3] |

|---|

Reference

[1]Bandsaw Hub, Horizontal Band Saw vs. Vertical Band Saw – Which is Best for You? [Online]. Available: https://www.bandsawhub.com/horizontal-band-saw-vs-vertical-band-saw/

[2]OnlineSupply, How to choose the best band saw blade, 24-Nov-2020. [Online]. Available:https://onlinesupply.ca/blog-section/choose-band-saw-blades

[3]Dakin Flathers, BAND SAW BLADE TEETH PER INCH (TPI) CHART, [Online]. Available: https://www.dakin-flathers.com/blog/bandsaw-blade-teeth-per-inch-tpi-chart

[4]University of Waterloo, ENGINEERING STUDENT SHOPS - Equipment, [Online]. Available: https://uwaterloo.ca/engineering-student-shops/equipment

Contributors:

| User | Last Update |

|---|---|

| Lesley Lang | 1233 days ago |

| Former user (Deleted) | |

| Former user (Deleted) |