Machining

Table of Contents

Overview

Machining is the process of manufacturing parts using various machines with high precision and speed from raw materials. The machined raw materials are commonly known as work pieces. Utilizing large shop machinery, machining has become a very useful practice for designing, prototyping and building various parts for machines, systems and products. Machining is very good at making parts with smaller tolerances sometimes being able to create entire parts with code in CNC Machining.

Safety

Machining is essentially the process of removing material from what will become your working part. This is done by using any one of the machines reviewed in this section. This removal process comes with the inherent risk of projectile material which is made loose during machining. Whether you are using the lathe or even a simple hand drill, your safety and the safety of your fellow shop members should be paramount to how you conduct yourself in a machine shop.

Personal protective equipment is essential to your safety and should accompany appropriate attire for the machine shop. Being conscious of what you wear and how you are wearing it while machining is important. In general, loose fitting clothing should not be worn as many machines have rotating parts which may catch and pull the loose clothing. This also applies to the hair of our longer haired machine shop friends. It is a good idea to tie your hair up in a bun or a tied back ponytail (tucked away if your ponytail is very long).

Eye protection is a must when using machine tools. When using the University of Waterloo Engineering Student Machine Shop you must always be wearing safety glasses.

It is a good idea to wear comfortable attire that covers as much skin as you are comfortable in. This is in case you have hot material fly off and land on you. Your clothes should be close-fitting, and you should remove all jewelry prior to machining.

After your rough work is done on your piece, be conscious of the rough edges and corners that your machining may have created. Burrs and serated edges are common cutting hazards produced by machining. Until a piece is properly finished it should be handled with care.

Be mindful of machine shop staff if working in a shop. It is a good idea to follow their guidance. On site staff will be your key to staying safe when you feel uncomfortable with a machining process new to you. If you are working with your own machinery, make sure you use the buddy system and have someone present with you in case of emergency. [1]

Always be mentally present and aware of your surroundings when operating machine or hand tools. Focus on your tasks and understand the inherant dangers or operating whichever tool you may need.

Drill Press

Drill presses produce a round hole in a workpiece by using a rotating tool (drill bit) with two cutting edges. They descend in a one dimensional angle onto the workpiece. The drilled hole may be either a through hole or a blind hole. In a through hole, the hole exits the opposite side of the work piece, whereas in a blind hole, the hole does not exit the opposite side of the workpiece. [2]

It is important to ensure you have selected the right drill bit before operating the machine. Drill bits come in four types at the UW Engineering Student Machine Shop: Metric, Fractional (Imperial), Letter, & Number. The drill bit is secured to the drill press chuck which will be fixed to the motor axle that transmits the rotary force.

The drill press with the appropriate bit can cut a somewhat accurate hole into most materials. When further precision is required, use a drill bit ~1/32" smaller than your desired hole diameter. Then replace the drill bit with a reamer that is the size your require for your hole. This process is better but if even furthere precision is required the chuck of the drill press will have to be replaced with a special chuck that has an adjustable cut piece as seen in Drill Press image 2. The cutting edge of the boring head is adjustable to cut to the exact precision required.

As with any rotating tool, loose clothing, hair, or jewelry should be removed or tucked away at a safe distance from any rotating parts. Edges of holes may be rough so ensure to clean loose material off with care.

Drill Press Image 1: Two types of drilled hole: (a) through hole and (b) blind hole. [2] |

|---|

| Drill Press Image 2: Boring Head Animation Cutting 2" Hole [3] |

|---|

Lathing / Turning

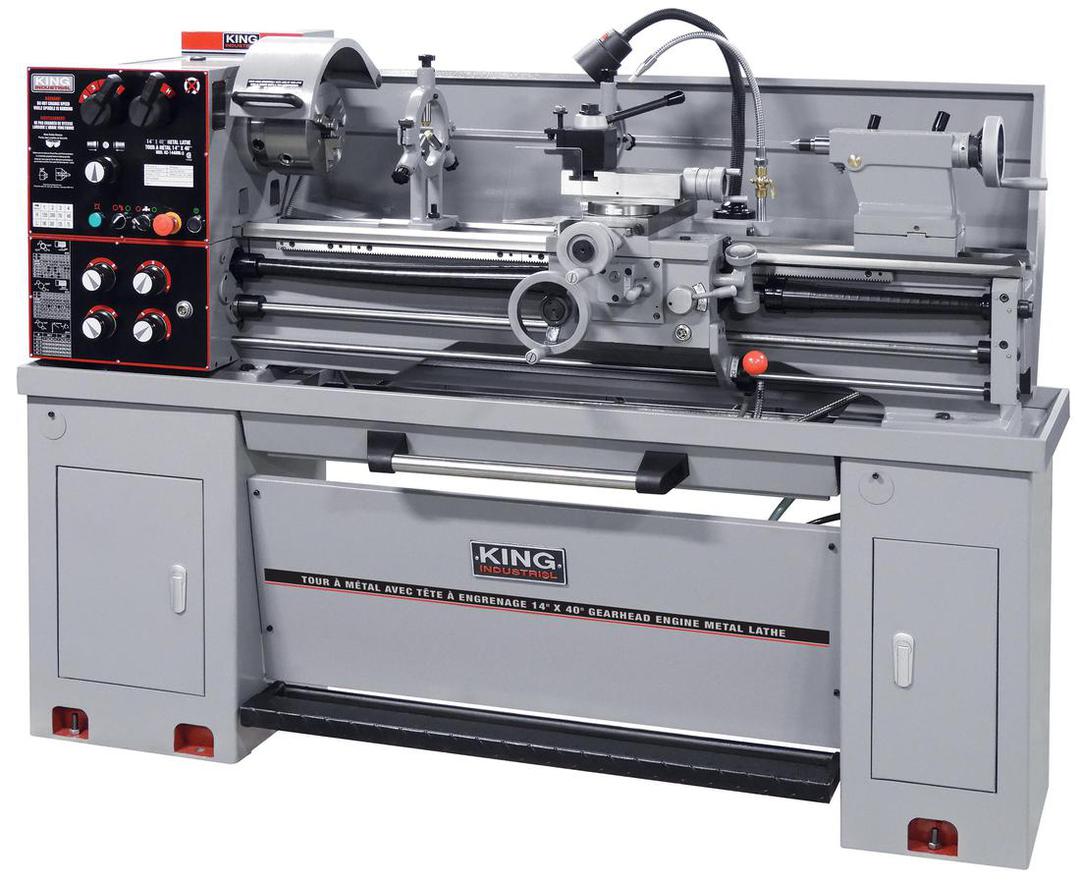

Lathing, also known as turning, is the method of machining by rotating work at a high speed around an axis to create concentrically symmetrical features. It is used for cutting, surfacing, shaping, threading, knurling, hand-turning and more with various tools that are brought to the work [8].

Lathes can have many functions due to the interchangeable tooling to create different results in the work. Lathes come in two main forms, machining lathes, commonly for precise, metalwork and wood lathes, more for hand turning and artistic work or other woodworking. Lathes can be of many sizes ranging from desktop lathes to large industrial lathes dozens of meters long. The chuck is the part of the lathe that your workpiece is afixed to. In the UW Engineering Student Machine Shop make sure to remove the chuck after use.

The rotational machine parts are a significant hazard. This is why you should always contain your long and loose hair, wear close fitting clothing, remove all jewelry, and NEVER wear gloves while operating a lathe. Any loose article may be pulled in by the lathe and lead to catastrophic injury or even death. As always, you should wear eye protection to ensure none of the material made loose enters your eye. You'll want a good foothold so be sure to wear sturdy footwear. NEVER leave the lathe running unattended. Ensure all guards are in place. After use or when too much loose material accumulates, stop the machine, and then remove all loose material in order to prevent the machine from grabbing and hurling the loose material.

When preparing to use the lathe, make sure your chuck is secured to the lathe. Then ensure your workpiece is firmly secured in the chuck. Adjust your material removal piece to the desired location. Special attention should be paid when you are manually removing material with a hand tool. Ensure the tool is held firmly or secured correctly when using a machine fixed tool.

The lathe is used to remove material concentrically. You can either remove material from the outer edge of a workpiece or the centremost part of the piece. In order to remove from the centremost part adjust your tool post (where material removal piece us fixed to) and gently move the tool into your workpiece.

| Machining Lathe |

|---|

| Lathe Chuck [9] |

|---|

Milling

Milling is the process of of machining where rotary cutters are used to remove material by advancing a cutter into a workpiece. This can be done by varying many different factors like cutter head speed, utilizing several axes, and pressure. It is one of the most commonly used processes for machining parts to the desired tolerances. There are a wide range of tools that can be used for milling. [4] A milling machine is like a drill press in the sense that it has a simple rotating piece that handles the material removal. It differs though in that it works in 3 dimensions as it is designed for cutting pockets like the one seen in the image to the side.

Milling machines have a vice to secure the workpiece to the machine's table [1]. Ensure that you square the vise to the table (parts cannot be properly squared if the vise is not). Material removal from the workpiece is done by feeding your workipiece through the cutting tool while it's fixed to the table. Some common functions of the milling machine are:

- Squaring a round workpiece

- Milling parts to size

- Cutting slots into work pieces

- Drilling holes

- Face milling (flattening a surface)

The tool used will depend the desired outcome of your workpiece. Make sure to ask the technicians or

Prior to using the milling machine, inspect the workspace and remove all potential hazards. Ensure the tool holder and tool itself are secure to the machine.

| Milling Machine [5] |

|---|

Water Jet

A water jet, also known as a water jet cutter, is an industrial tool capable of cutting a wide variety of materials using an extremely high pressure stream of water. A mixture of water and an abrasive substance can also be used. The term abrasive jet refers to the use of the mixture of water and an abrasive substance to cut hard materials like stone, metal or glass. On the other hand pure waterjet refers to water jet cutting using just water, and is used for softer materials like wood or rubber. This method is often used to fabricate machine parts. This method is also very useful when cutting objects that are sensitive to temperatures like plastic. Water jet is also used in industries like mining and aerospace.

| Water Jet Cutting Machine [6] |

|---|

Finishing

Finishing is the process of taking a recently fabricated piece and making it have a final surface finish and dimensions. When a piece is milled, 3D printed, machined or fabricated in any other way, the piece will usually not be in its final form. There are usually rough, sharp and/or burred edges, undesired surface finish, not be in its final dimension or any other small issues machining has caused. Finishing is the process of handling these issues to ensure the final piece is to specification. Various methods can be used for finishing. Finishing passes, sanding, polishing, and more can be utilized to achieve a finished product once initially fabricated.

| Comparison of an Unfinished Part (Left) and a Finished Part (Right) |

|---|

Hand Tools

Hand Drills

As describribed above, a hand drill produces a hole in a 1 dimensional angle. Like the press, it can cut through or blind holes. Some models are battery powered others are plug in. It is best to fasten your workpiece well before drilling a hole or your hole will be less clean and your piece may fly off.

As the drill bit spins rapidly, loose articles such as clothing or hair should be kept away from moving part. Remove all jewelry prior to handling drill. Ensure you have the proper size and type of bit for your work.

The hand drill is advantageous because it can be used wherever you need it unlike the bulky press. However, it is siginificantly less accurate than the press as the operator's strength and proficiency play a great role in its handling.

Jig Saws

Angle Grinders

Rotary Tools

Chisels

Files

Wrenches

Hammers

| Corded Hand Drill Example [8] |

|---|

Contributors:

User Last Update