Butterfly Valve

Table of Contents

Figure 1. Butterfly Valve: Opened and Closed [1] |

|---|

What are Butterfly Valves?

Butterfly valves are among the family of quarter-turn valves and work very similarly to ball valves [1]. This valve is composed of a disk labeled the "butterfly" that is connected to a rod; it is opened and closed by rotating the rod, which subsequently rotates the disk, by 45° from its initial position. It is open when the disk is parallel to the water flow and it is closed when the disk is perpendicular to the water flow.

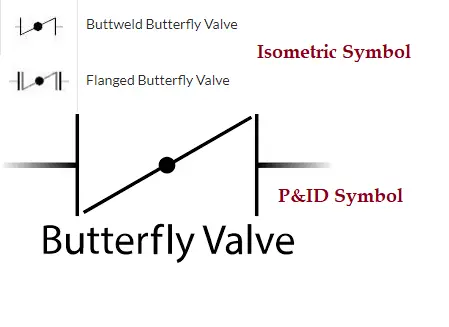

Figure 2. Anatomy of a Butterfly Valve [1] | Figure 3. Butterfly Valve Symbols [2] |

|---|---|

Advantages | Disadvantages |

|---|---|

|

|

Applications

In the pharmaceutical, chemical, and food industries, a butterfly valve is used to interrupt product flow (solid, liquid, gas) [2]. Butterfly Valves have mostly replaced ball valves in the petroleum industry due to their lower cost and ease of installation.

More generally they are used in the following industries and areas; water supply, wastewater treatment, slurry services., fire protection, air and gas supply, vacuum services, lubrication system, chemical and oil industries, fuel handling systems, power generation, compressed air and gas services, steam services, food processing, pharmaceutical, marine system, sanitary valve application. [2]

Overall butterfly valves are good for constant load applications, space-restrictive applications and throttling valves. [2]

Types of Butterfly Valves

Connection design

| Wafer-Style | Lug-Style |

|---|---|

| The wafer style is the most economical and is sandwiched between two pipe flanges. Both pipe flanges on each side are connected by long bolts across the body of the valve. The sealing between the valve and pipe flanges is ensured by gaskets, O-rings and flat valve faces. This style is designed for sealing against bi-directional differential pressures and to prevent backflow in systems designed for universal flow. [1] | The lug-style has threaded inserts around the valve body. A pair of bolts from each pipe flange on both sides connect via the threaded inserts adding up to 8 pairs in total. This design allows for disconnection of one side throughout service without affecting the other side, but only at low pressures. The lug-style valves, unlike the wafer-style, support the weight of the piping throughout the valve body. [1] |

Figure 4. Wafer-Style Valve [1] | Figure 5. Lug-Style Valve [1] |

|---|---|

Actuation Method

| Manual | Automatic |

|---|---|

Manual actuation methods are cheap and are easy to implement and operate. Hand lever: Self-explanatory. Used for small and simple piping needs. Gear: Used for slightly larger butterfly valves. Uses a gearbox to increase torque at the expense of decreased speed of opening/closing [1]. | Automatic actuation methods are very reliable when operating from a remote area. Fail-safes can easily be integrated into their design. Electric: An electric motor is used to turn the valve. Pneumatic: Compressed air is used to open and close the valve. Hydraulic: Uses Hydraulic pressure to open and close the valve |

Materials

Below is a table showing different materials that can be used for each part of a butterfly valve.

Figure 6. Material options for valve body, disc, stem and seat [2] |

|---|

References

Contributors:

| User | Last Update |

|---|---|

| Former user (Deleted) | 1400 days ago |

| Former user (Deleted) | 1412 days ago |

| Former user (Deleted) | 1444 days ago |

| Former user (Deleted) | 1479 days ago |