Check Valve

Table of Contents

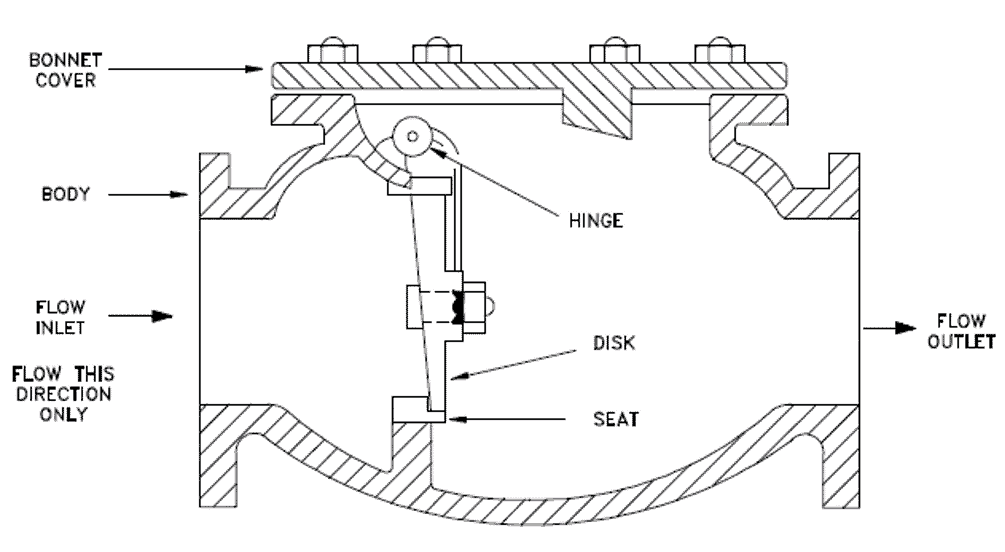

| Diagram of a Swing Check Valve [2] |

|---|

What are Check Valves?

Check valves are used to prevent backflow and operate under pressure difference [1]. They open when pressure is greater on the inlet side. The minimum operational pressure to allow water flow to pass through a check valve is called the cracking pressure. Check valves are most commonly used in water management systems as well as many industrial applications. Common types of check valves include swing check valves and lift check valves.

Types of Check Valves

- Ball check valve

- Swing or butterfly check valve

- Spring check valve

- Lift or globe check valve

- Diaphragm check valve

- Tilting disc check valve

- Pneumatic check valve

Water Hammer

Also known as valve slam, water hammer is the reversal of flow before the valve can close completely [1]. When the flow of water is forced to stop, but water behind it continues to flow, it causes water compression. The accumulation of kinetic energy converts to pressure, and results in a hydraulic shock wave. A huge water hammer can be fatal to pipelines and water systems, and can cause huge setbacks for companies in repairs. In any case, if water hammer repeats, the efficacy of the water system and the valve will be compromised.

Advantages

- Prevent backflow

- Self-operational [3]

- Many applications make use of check valves

Disadvantages

- Do not work with pulsating systems [3]

- Difficult to maintain zero leakage, water hammer can occur and damage the valve/system

- Difficult to check on the status of the valve

Applications

Check valves are widely used in many industries. Here are some applications of check valves [1]:

- Industrial processes

- Water pumps and pipelines

- Food and beverage production

- Water and wastewater treatment

- Chemical processes

Materials

The chart below outlines some characteristics of the materials commonly used in check valves. Temperatures listed below are a very rough approximate. These values will differ depending on the size and grading of the check valve [4].

| Material | Temperature (°C) | Characteristics |

|---|---|---|

| Brass | -200 ~ 200 |

|

| Stainless Steel | -254 ~ 816 |

|

| Ductile Iron | 0 ~ 350 |

|

| Bronze | -30 ~ 300 |

|

| PVC | Up to 60 |

|

| Polypropylene | Up to 80 |

|

Choosing a Check Valve

Although material selection is very important when choosing what check valve to use, it is also important to consider the following [1]:

- Flow rate - how quickly the medium will be handled by your check valve (measured in GPM, GPH, or L/S).

- Cracking pressure - minimum pressure required to open the check valve (measured in PSI).

- Dimension/fitting - how the check valve will be connected. Reference supplier pages to find exact specifications of check valves.

More information on how to choose valves can be found on the Specifying Valves page.

Contributors:

| User | Last Update |

|---|---|

| Former user (Deleted) | 1425 days ago |

| Former user (Deleted) | 1426 days ago |

| Former user (Deleted) | 1445 days ago |

| Former user (Deleted) | 1504 days ago |

Faculty Advisor: Rachel Malevich (alumni)