Seals

What are Seals?

Seals are devices that are primarily used to prevent leakage of fluids between two mating surfaces and minimize the friction and wear of moving parts [2]. Seals can be used on parts that move linearly or radially. They are commonly used in pumps, compressors, automobiles and various other machinery.

Common Types of Seals

There are a number of different types of seals which differ based on their physical properties and which applications they are best suited for. Some of the more common types of seals include Gaskets, O-Rings, Standard Mechanical Seals, and Rotary Shaft Seals [3].

| Assorted Gaskets [4] |

O-Rings

O-rings are a type of mechanical seal that has a round cross section [5]. They are typically used to prevent fluid leaks because they are cost-effective and can withstand high pressures [5]. O-rings are installed into a groove in one surface where they are compressed against another surface to create a seal. To select an o-ring material, you must consider the material's compressibility, performance in various substances (oils, acids, bases, steam, fuels, corrosive chemicals), wear resistance, performance in various temperatures, permeability, and of course cost [5]. Common o-ring materials are Nitrile (Buna-N), Ethylene Propylene Rubber (EPR), Fluorocarbon (Viton), Neoprene, Polyurethane, Silicone, Polytetrafluoroethylene (PTFE), Perfluoroelastomers (FFKM), Ethylene Propylene (EPDM), and Fluorosilicone [5]. O-rings are very versatile seals which allow them to be used in a multitude of applications from water pumps to rocket engines [5].

Custom and Standard O-Rings

USA AS568 o-rings are the most commonly used o-ring sizes and Marco Rubber and Plastics offers every standard size of USA AS568 o-rings and can make custom o-rings for your specific application [6].

O-Ring Tolerances

When selecting an o-ring it is very important that you have the correct tolerances and Marco Rubber and Plastics has tolerance charts for USA AS568 and general purpose o-rings to help you properly size your o-ring groove.

| Assorted O-rings [5] |

Gaskets

Gaskets are a type of mechanical seal that fill in the irregularities between two or more mating surfaces in order to prevent the leakage of fluids [7]. They are best suited for two mating surfaces that do not have a perfect surface finish. For a gasket to work properly, the gasket must be compressed with enough force to generate the desired seal between the irregular surfaces, preventing fluid leakage. Since gaskets connect two surfaces together and fill in deformities, they are manufactured from materials that are easily deformed when under pressure and tightly fill in any gaps or irregularities between the mating surfaces [8]. Possible gasket materials include Nitrile (Gasket Paper), Silicone, Fiberglass, Thin Sheet Metal, Cork or Polytetrafluoroethylene (PTFE) [5]. Gaskets are commonly found in a range of low to high pressure applications and are used to seal stationary components. Notable examples of gaskets include in the automotive industry, such as the head gasket, which is compressed between the engine block and cylinder head. Another application is flange gaskets, that are placed between connecting pipes and prevent leakage of the fluid and minimizes vibrations [9]. Felpro is a large automotive gasket manufacturer.

| Head Gasket on top of Engine Block [10] | Flange Gasket [9] |

Torqueing for Gaskets

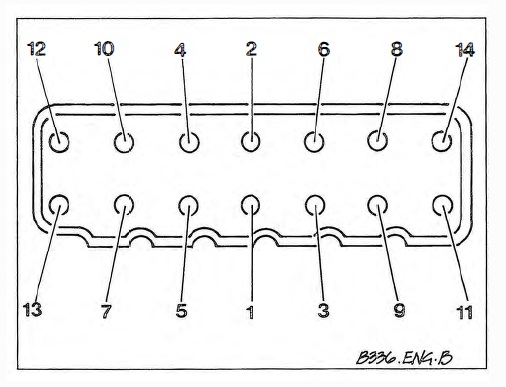

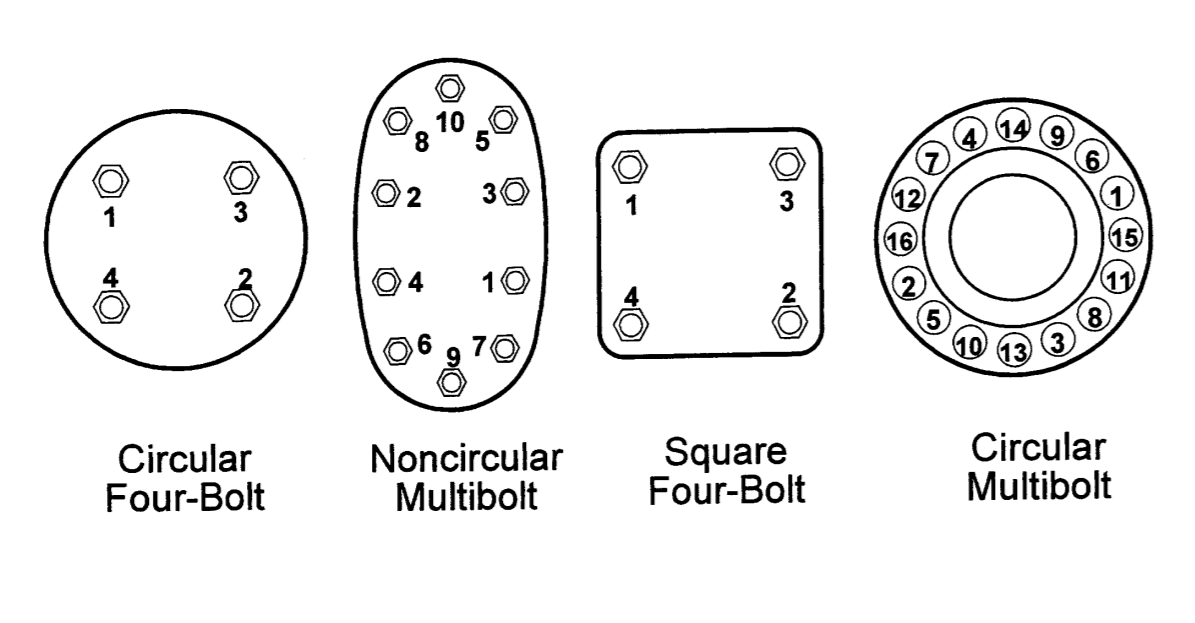

All gaskets need to be torqued down to meet a specification to ensure the gasket slightly deforms to fill in the irregularities between the two surfaces and create the desired seal. Improper tightening of gaskets such as under tightening and over tightening can lead to large failures of the gaskets, causing a lot of damage to whatever surfaces they are mating together [11]. If a gasket is under tightened, the desired seal may not be created due to insufficient pressure, causing the leakage of any fluids. Overtightening a gasket may over compress the gasket, meaning it will develop weak spots where it can fail earlier than expected [12].

To ensure that gaskets are tightened to specific torque requirements, a gasket must be torqued down based on the torque specifications given by the manufacturers. When it comes to head gaskets on vehicles, it is best to follow the torque specifications stated in the owner's manual. To torque gaskets, a torque wrench can be used and a torqueing pattern must be followed (which is also stated by the manufacturer). These torqueing patterns ensure that pressure is applied evenly to the entire gasket rather than concentrating stress into one place. Torqueing patterns on head gaskets usually start in the center and spiral outwards to the ends of the gasket [12].

| Typical Head Gasket Torque Pattern [13] | Gasket Torque Patterns on Other Forms of Gaskets [14] |

Laser Cutting Gaskets

Most rubber and synthetic gaskets are chlorinated, so when they are laser cut, they let off gas chlorine gas which is very toxic. If you have to laser cut a gasket, check that it is non-chlorinated. McMaster-Carr has vegetable fiber gaskets that are non-chlorinated and have been safely laser cut before.

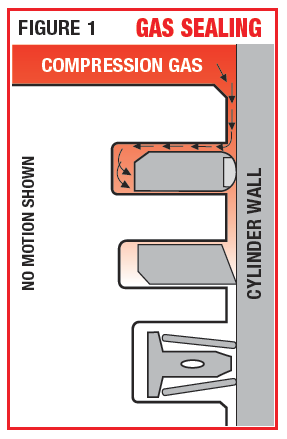

Piston Rings

Piston rings, mainly found around the pistons of an internal combustion engine, are used to ensure an engine is operating efficiently and outputting sufficient power [15]. Piston rings are usually a split ring and attach to pre-made grooves in the cylinder. Piston seals have three main functions which are; compression gas sealing, oil film control, and improving heat transfer [15]. There are usually three types of piston rings that are attached to an automotive piston, the top two rings are compression rings and the bottom ring is an oil control ring. The compression ring (near the piston head) creates a seal between the cylinder and piston to prevent any leakage of combustion gasses and pressure. This is critical for ensuring the engine is not losing any of its power, which would reduce efficiency. This seal between the moving piston and stationary cylinder is created by the preset outwards spring force of the ring (inherent pressure) and the heat expansion of the ring due to the hot combustion gasses [16].

The oil control ring (bottom ring) regulates the film of oil between the cylinder and piston as it scrapes away excess oil, only leaving behind a thin film of oil to minimize friction and heat, and improve the lifetime of the engine [17]. The second ring is a combination of both compression and oil control rings, but focuses more on maintaining this film of oil. Additionally, all three rings aid in heat transfer, as they transfer the heat generated during combustion from the piston head to the entire cylinder.

| 3 Types of Piston Rings [16] | Cross Section of Piston Rings [17] |

Mechanical Seals

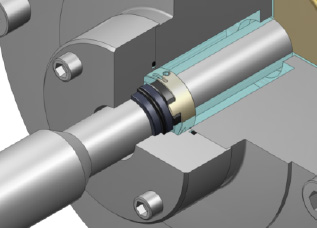

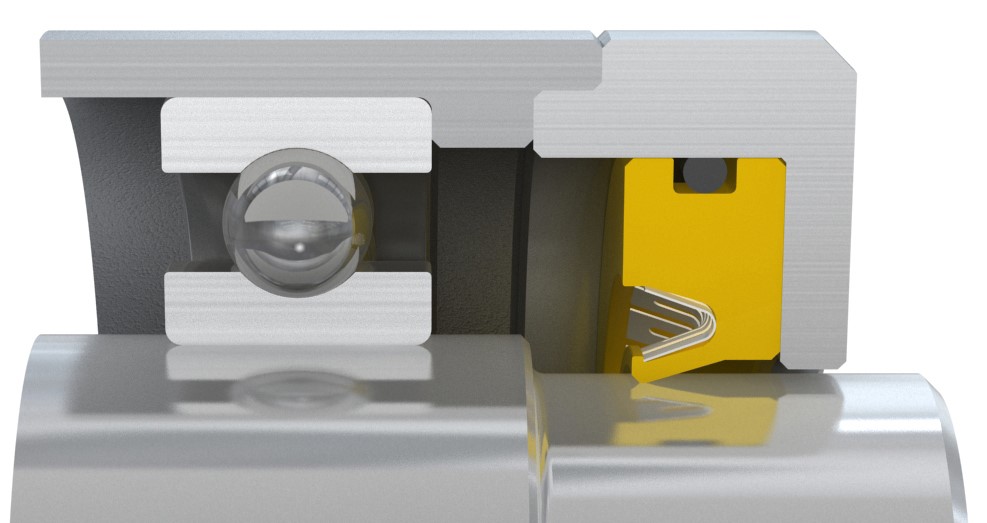

End Face Mechanical Seals are a type of mechanical seal which are commonly used in pumps, compressors and mixers. They are typically found in automobiles (water pump), petroleum refineries, and chemical plants [18]. The main purpose of this device is to create a seal between a rotary shaft and stationary housing by utilizing the clearance between the two parts, to minimize leakage of any fluids and ensure sufficient lubrication [2]. End Face Mechanical Seals are typically comprised of two main rings; a rotary ring that spins with the shaft, and a stationary ring that is attached to the housing of the pump. The two rings rub against each other with very specific amounts of clearance between them, creating a thin film of fluid between the shaft and the housing, that minimizes friction between the parts, while also not hindering the movement of the shaft [2]. The clearance is specific so that there is not too much friction to wear out the shaft or too little clearance that can cause leakage of the fluid.

| End Face Mechanical Seal Found in a Pump [2] | Two Rings of an End Seal [2] |

Bellow Seals

Bellow seals are a type of mechanical seal that use thin sheets of metal in the shape of a bellow to create a seal between a shaft and a hollow tube or cylinder [19]. Bellow seals are typically used in harsh conditions such as corrosive chemicals, cryogenics, and temperatures as low as -350°F to as high as 650°F [19]. The bellow seal's all-metal construction allows it to withstand a much larger range of temperatures than rubber based seals [16]. Bellow seals are often used in valves where they prevent the fluid in the valve body from escaping around the valve stem [20]. Some valves even have a leak detection port to inform the operator of when the seal needs to be replaced [20]. There are two different types of bellows [21], which are shown on the right. The rolled bellow is made from a single sheet of metal and is bent into an oscillating curve. The other type of bellow is a welded edge bellow, where the bellow is made of alternating male and female diaphragms that are welded together around the circumference [21].

| Rolled Bellow Sectional View [22] | Welded Edge Bellow Sectional View [23] |

Rotary Shaft Seals (Lip Seals)

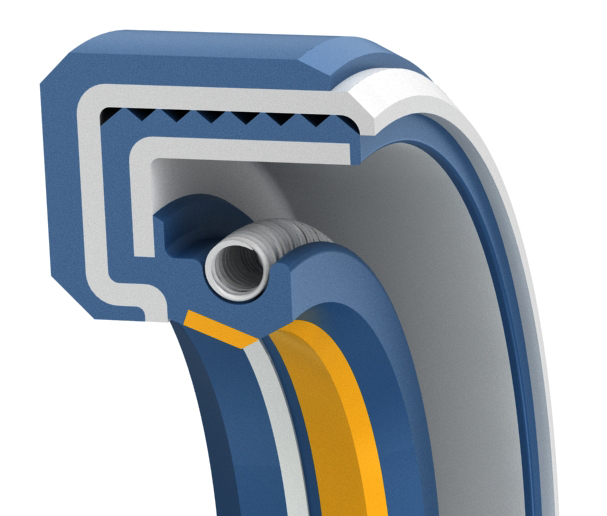

Rotary Shaft Seals are a type of seal that are commonly found in devices with rotating or oscillating components [24]. These seals help improve the reliability and efficiency of these devices. Such devices include hydraulic pumps, hydraulic cylinders, gearboxes, and power steering systems. Rotary Seals have two main functions; sealing function and wiping function, to minimize lubricant leakage and remove contaminants. The first function is to retain the bearing lubricant in the housing and prevent leakage. The second function is to actively remove and prevent any contamination from entering the housing, which may damage the bearing and shaft [24]. This seal is constructed of two main parts; an outer covering and a sealing lip. The outer covering (seen below in blue), is made from sheet metal or an elastomer and sits against the housing bore with an interference fit to create one seal. The sealing lip, made from a flexible plastic (elastomeric), creates a dynamic seal against the surface of the shaft, and has an angled component that can actively remove/prevent any contamination from penetrating the seal. The sealing lip is pressed against the shaft with a defined amount of force, which is controlled by a garter spring, that runs axially around the shaft as well (seen below as a white tube) [25].

| Cross Section of a Rotary Shaft Seal [26] | Cross-Section of Rotary Seal on Shaft [26] |

Labyrinth Seals

Labyrinth seals are a type of seal that uses a maze-like structure that prevents contaminants and splashing liquids from passing the seal. Labyrinth seals are typically used to protect a bearing from contaminants which prevents premature bearing failure. Labyrinth seals are non-contact seals because they do not contact the shaft they are around, which means that using labyrinth seals does not lower system efficiency or generate heat. Labyrinth seals can last forever as long as they are not exposed to extreme contaminants as they do not wear because there is no friction between the seal and the shaft. GMN Bearing USA is a labyrinth seal manufacturer who sell four types of labyrinth seals. Type L labyrinth seals are a standard labyrinth seal that uses an inner ring of steel and an outer ring of aluminum. Type M labyrinth seals are a heavy duty labyrinth seal that have passage ways to allow large contaminant particles to be centrifuged out of the seal. Gap seals are a plastic labyrinth seal designed for use with chemicals, bacteria, fungi, and water. CF labyrinth seals are a new type of labyrinth seal made of aluminum, that seal directly onto a bearing which means that you don't need extra space to mount a labyrinth seal and they are 100% seal efficient [27].

| Labyrinth Seals [28] |

V-Ring Seals

V-ring seals are a type of axial shaft seal that are made from a rubber ring with a v-shaped cross section. V-rings seal in the axial direction to prevent contaminants from passing through to the bearing, which prevents premature bearing failure. These seals are mounted to the shaft using an elastic fit which allows the system to seal even if the shaft is eccentric or the shaft is misaligned. Daemar is a v-ring seal manufacturer who sell four types of v-ring seals. VA v-ring seals are the standard type of v-ring seal that are used in conveyor belts and appliances. VS v-ring seals are the wide type of v-ring seal that feature an angled rear section for sealing at higher speeds. VS v-ring seals are used in automotive and agricultural applications. VL v-ring seals are the narrow type of v-ring seal that have a thinner cross section for applications with limited space, such as pillow block bearings. VE v-ring seals are the heavy duty type of v-ring seal that have a longer cross section for applications with a large diameter shaft, or where there is increased shaft misalignment. VE v-ring seals are typically used in mills to keep contaminants out of roller bearings [29].

| Standard VA V-Ring Seal [29] |

Silicone Sealant

Silicone sealant is a liquid adhesive and a very versatile seal. Silicone sealant is often purchased as a type of caulking and is used to seal joints. Silicone sealant comes out of the tube as a viscous liquid and it can take anywhere from a day to several days to fully cure [30]. There are 3 main types of silicone sealant [30]. High temperature sealant can with stand temperatures as high as 600°F and is often used in the automotive industry to seal parts of engines or in industry to seal ducting or in place of a gasket [30]. Electric grade self-leveling sealant does not contain corrosive chemicals and it is highly resistant to weathering, moisture, sun, and moderately extreme temperatures [30]. Electric grade self-leveling sealant is often used on materials that are constants exposed to the elements such as glass, wood, metal, ceramic, or plastic [30]. Multi-purpose sealant is resistant to weathering, moisture, vibrations, and moderately extreme temperatures and can be used on aluminum, ceramic, glass, metal, wood, plastic, granite, and many other surfaces [30]. Multi-purpose sealant is great for residential repairs and can often be found around windows, sinks, showers, and bathtubs. When using silicone sealant wear safety glasses, gloves, and a respirator because inhaling silicone vapor and any direct contact between uncured silicone sealant and your skin and eyes is bad [31].

| Silicone Caulking [32] |

References

[1] Bearings & Industrial Supply, Seals. Accessed on: Feb. 25, 2021. [Online]. Available: https://www.bearingsandindustrialsupply.com/seals.html

[2] EKK Technologies, Mechanical Seals. Accessed on: Jan. 19, 2021. [Online]. Available: https://www.ekkeagle.com/en/technology/mechanical/

[3] Real Seal, Different Types of Seals and the Applications that Rely on Them, Jan. 19, 2017. Accessed on: Jan. 18, 2021. [Online]. Available: http://www.real-seal.com/blog/different-types-of-seals-real-seal/

[4] Ashish2117, Europe Automotive Gasket and Seal Market Development Insights - Ken Research - Power Point PPT Presentation, PowerShow. Accessed on: Feb. 25, 2021. [Online]. Available: https://www.powershow.com/view0/8a0ee8-ZWRmN/Europe_Automotive_Gasket_and_Seal_Market_Development_Insights_-_Ken_Research_powerpoint_ppt_presentation

[5] Thomas Net, O-Ring Types and O-Ring Material Makeup - A Guide. Accessed on: Jan. 25, 2021. [Online]. Available: https://www.thomasnet.com/articles/hardware/o-rings-material-makeup/

[6] Marco Rubber and Plastics, O-ring Size Chart for USA AS568 Standard O-Ring Dimensions. Accessed on: Feb. 23, 2021. [Online]. Available: https://www.marcorubber.com/o-ring-size-chart-as568.htm

[7] Robco University, What are Gaskets?. Accessed on: Jan. 31, 2021. [Online]. Available: https://robco.com/en/what-are-gaskets

[8] Barnwell, What is a Gasket?. Accessed on: Jan. 30, 2021. [Online]. Available: https://www.barnwell.co.uk/what-is-a-gasket/

[9] Projectmatierals, Types of Gaskets for Flanges, Sept. 20, 2017. Accessed on: Feb. 1, 2021. [Online]. Available: https://blog.projectmaterials.com/gaskets/gasket-for-flange-asme/

[10] BlueDevil Products, Is Fixing a Blown Head Gasket Worth It?. Accessed on: Feb. 1, 2021. [Online]. Available: https://gobdp.com/blog/is-fixing-a-blown-head-gasket-worth-it/

[11] S. Shelton, Head Gasket Torque Specs, ItStillRuns. Accessed on: Feb. 22, 2021. [Online]. Available: https://itstillruns.com/head-gasket-torque-specs-7732348.html

[12] Fel-Pro, Torque Tables, 2009. Accessed on: Feb. 22, 2021. [Online]. Available: https://drivcat.com/livedocs/99999.pdf

[13] Garlock Sealing Technologies, Rubber Gasket Installation & Torque, June, 2014. Accessed on: Feb. 22, 2021. [Online]. Available: https://www.garlock.com/sites/default/files/documents/en/Rubber-gasket-(full-face-in-flat-face-flanges)-Installation-&-Torque.pdf

[14] Gasketech, Causes of Blown Head Gaskets, Sept. 13, 2017. Accessed on: Feb. 22, 2021. [Online]. Available: https://gasketech.com.au/causes-of-blown-head-gaskets/

[15] TPR, What is a Piston Ring?. Accessed on: Feb. 21, 2021. [Online]. Available: https://www.tpr.co.jp/tp_e/products/pistonring/about.html

[16] Race Winning Brands, Piston Ring Tech, Performance Motorsports. Accessed on: Feb. 21, 2021. [Online]. Available: https://www.performancemotorsports.eu/support/instructions-terminology/piston-ring-tech/

[17] University of Windsor, Piston and Piston Rings, University of Washington. Accessed on: Feb. 21, 2021. [Online]. Available: https://courses.washington.edu/engr100/Section_Wei/engine/UofWindsorManual/Piston%20and%20Piston%20Rings.htm

[18] Robco University, What are Mechanical Seals?. Accessed on: Jan. 27, 2021. [Online]. Available: https://robco.com/en/what-are-mechanical-seals

[19] American Seal & Packing, Metal Bellows. Accessed on: Jan. 26, 2021. [Online]. Available: https://www.mechanicalseals.net/Metal_Bellows.htm#:~:text=Metal%20bellows%20seals%20feature%20a,with%20synthetic%20rubber%20sealing%20members

[20] Inst Tools, Bellow Seal Valve Working Principle. Accessed on: Jan. 26, 2021. [Online]. Available: https://instrumentationtools.com/bellows-seal-valve-working-principle/#:~:text=A%20completely%20different%20approach%20to,proof%20seal%20with%20negligible%20friction.&text=One%20end%20of%20the%20bellows,welded%20to%20the%20protective%20tube

[21] AES Seal, Metal Bellows Range. Accessed on: Jan. 26, 2021. [Online]. Available: https://www.aesseal.com/en/resources/video/metal-bellows-range

[22] Bellowman Technology, Metal Expansion Joints. Accessed on: Jan. 26, 2021. [Online]. Available: http://www.bellowman.com/en/products/metal-expansion-joints/end-connections.html

[23] john crane, 7 THINGS TO KNOW BEFORE SELECTING WELDED METAL BELLOWS SEALS FOR YOUR APPLICATION, Feb. 25, 2020. Accessed on: Jan. 26, 2021. [Online]. Available: https://www.johncrane.com/Resources/Blog/2020/7-things-to-know-before-selecting-welded-metal-bellows-seals-for-your-application

[24] Parker, Rotary Shaft Seal. Accessed on: Feb. 9, 2021. [Online]. Available: https://ph.parker.com/ca/en/rotary-shaft-seals

[25] SKF, Radial shaft seals: static and dynamic performance. Accessed on: Feb. 9, 2021. [Online]. Available: https://www.skf.com/ca/en/products/industrial-seals/power-transmission-seals/radial-shaft-seals

[26] American High Performance Seals, AHP5. Accessed on: Feb. 9, 2021. [Online]. Available: https://www.ahpseals.com/product/ahp5/

[27] GMN Bearing USA, Labyrinth Seals. Accessed on: Feb. 25, 2021. [Online]. Available: https://www.gmnbt.com/labyrinth-seals/

[28] M. Santora, What are labyrinth seals for bearings?, Bearing Tips, July 16, 2018. Accessed on: Feb. 25, 2021. [Online]. Available: https://www.bearingtips.com/what-are-labyrinth-seals-for-bearings/

[29] Daemar Inc, V-Rings. Accessed on: Feb. 25, 2021. [Online]. Available: https://daemar.com/v_rings_40.html/

[30] Hotmelt, Silicone Sealant Handbook. Accessed on: Mar. 10, 2021. [Online]. Available: https://www.hotmelt.com/blogs/blog/silicone-sealant-handbook

[31] GC Eletronics, Silicone Sealant/Adhesive MSDS, Farnell, Jan. 29, 2013. Accessed on: Mar. 10, 2021. [Online]. Available: https://www.farnell.com/datasheets/1799211.pdf

[32] Bostik Smart Adhesives, Understanding Silicone Sealants for Construction. Accessed on: Mar. 10, 2021. [Online]. Available: https://www.bostik-industrial.com/4380-2/

Contributors:

| User | Last Update |

|---|---|

| Mayurakhi Khan | 1229 days ago |

| Former user (Deleted) | |

| Former user (Deleted) | |

| Former user (Deleted) | |

| Former user (Deleted) |

Faculty Advisor: Chris Rennick, Michael Lenover (Alumni)