...

| Expand | ||

|---|---|---|

| ||

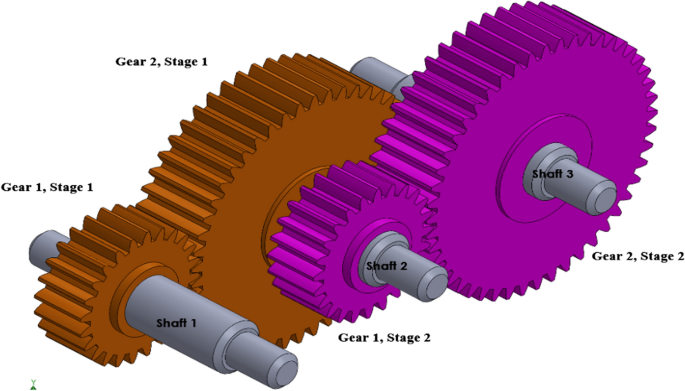

Operation Fundamentals Spur/helical/bevel gears are probably the most common types of transmission. They transmit varying torque and power pretty much exactly as explained in 9 - Power Transmission, so check out that page if you want to figure out how the gears work. Spur gears and helical gears are very common in their operations, and both types of gear typically feature two parallel gears that mate together. The only difference between the two are that spur gears feature straight cut teeth, where as helical gears have angular cut teeth. Helical gears have a higher contact ratio on the teething than spur gears, allowing for higher torque and speed transmission for the same size at the cost of a higher axial gear load. Helical gears are used more commonly in robotics due to their higher torque transmission, but to use them over spur gears you do need to account for the additional axial thrust loads. Also, helical gears can be used to transmit rotation and torque in perpendicular shafts, but I think there are better options to achieve this if necessary, as the mating design can get messy. Stock spur/helical gears are cut to operate at standard distances, defined by: Standard Centerline Distance = (Pinion Pitch Diameter + Gear Pitch Diameter) /2 Single stage helical and spur gears typically have pretty low reduction ratios, with the max reduction for spur gears reaching ~ 1:6 and max reduction for helical gears reaching ~ 1:10. However, the main benefit of helical and spur gears is that they allow for very high transmission ratio through multiple reduction stages. You can stack up multiple stages of transmission in a low profile of gears to achieve high transmission ratios, like shown below. This is likely overkill for our robot arm, but if we really need high transmission we can look into spur or helical gears as an option. When using these transmissions, we also need to consider that the backlash will stack up between mated teeth, so backlash could be increased. Bevel gears feature an angled tooth profile to allow the transmission of power to perpendicular shafts. Tooth profiles for bevel gears come in multiple forms, such as straight and spiral which offer the same benefits and drawbacks as discussed for spur vs. helical gears. Single stage bevel gears have an approximate standard max ratio of 5:1. However, bevel gears can improved by shifting to a hypoid gear design. In bevel gears, the two gear axis intersect at a center point. In a hypoid gear, the axis of the two gears are shifted by an offset, which allows for MUCH higher power transmission (up to 200:1)! However, hypoid gears are difficult to mesh properly, and require more maintenance (constant lubing) as the meshed teeth are under higher pressure. Backlash All gear types in this section require backlash to operate. Backlash is required to allow for the smooth operation of mating gears, and reduces friction by preventing grinding. If you run these gears at 0 backlash, they can seize and fail. I've been able to find some standard backlash gears for spur gears, but not for helical gears. Some sources say that helical gear backlash is lower than spur, but I haven't been able to find too many published values on this notion. These values relate directly to the standard centerline distance formula discussed above. Didn't find too many published values on backlash in bevel gears, as it's mostly dependent on centerline distance for mated gears, reduction ratios and suppliers. There are formulas posted for all types of gears, but as far as empirical values go I would assume backlash between spur and bevel gears is relatively close. General consensus is that these types of gears produce the highest amount of backlash as the types of transmission discussed on this page. To reduce backlash in spur and helical gears, the main two options are to change centerline distance in gears or adjust tooth thickness. For our design purposes, only changing centerline distance would really be a feasible option. As an alternative, there are vendors who offer split spur (but not helical, from what I've seen) gears that use split tooth profile and springs to reduce experienced backlash. These use a spring to push half of the split gears teeth into the open space to prevent backlash when gearing stops moving, but still allow for minimal backlash to occur due to the flexibility of the spring. These gears are pretty expensive (72 dollars each from some estimates) so alternate non backlash options can be explored. OTS Options Spur, standard beve; and helical gears are readily available from multiple gear manufacturers, with KHK being a really easy to access vendor. Hypoid gear models are more difficult to find and procure, from what I've seen they come from mainly international suppliers. Custom Manufacturability We could probably machine spur and straight bevel gears ourselves if we wanted to, however purchasing gears is a MUCH better alternative IMO. Custom machining gears is super unnecessary. Spur and helical gears require pretty precise tooth profiles to be accurate, so it's better to leave those designs for an expert. Helical and spiral bevel gears would probably be difficult to manufacture. Also, these types of gears aren't too expensive, probably ~ $35-75 each (approximations from KHK website). Recommended Joint Location Due to their inherent backlash, I don't think we should really consider any of these the main joints. However, they may be useful on the wrist or end effector where backlash considerations are less significant, as they can be used to increase reduction ratios through their multiple stage transmission and are relatively simple to install. Extra Resources https://khkgears.net/new/gear_knowledge/gear_technical_reference/gear_backlash.html https://www.motioncontroltips.com/hypoid-gearboxes-what-are-they-and-where-are-they-used/ |

- lead screws(?) need to look into this more

- worm gear

- planetary gear

Common Extra Resources