What are Pulleys?

Pulleys are wide cylinders, potentially with a groove for a cord or belt to fit in. Pulleys can change the direction of force, amplify the force through a mechanical advantage, or perform both functions [2]. Pulleys are generally used to make the task of lifting an object easier, pulling downwards is usually easier or safer than pushing upwards, and through the use of the pulley's mechanical advantage the force required to lift the load is less.

| One pulley changing the direction of force [2] | Two pulleys changing direction and providing a mechanical advantage [2] |

Types of Pulleys

Fixed Pulley

A fixed pulley is a pulley that is mounted to a stationary surface [3]. If a cord or belt is passed through a fixed pulley the pulley will rotate but not move. The main advantage of fixed pulleys is that they can redirect force [3]. A well uses a fixed pulley because it allows a person to lift a bucket of water by pulling a rope downward.

Fixed pulley used in a well [4] |

Moveable Pulley

A moveable pulley is a pulley that is mounted to a moveable surface (typically the load) [3]. If a cord or belt is passed through a moveable pulley, the pulley will rotate and move. The main advantage of moveable pulleys is they lessen the force required to move a load using mechanical advantage [3].

Moveable pulley load diagram [5] |

Compound Pulley System

A compound pulley system combines fixed and moveable pulleys to take advantage of the benefits of both types [3]. Construction cranes use a compound pulley system to lower the force required to lift construction materials and redirect the force to the other side of the crane where the motors and winch are to help counterbalance the load.

Compound pulley system used in a construction crane [6] |

Specialized Pulley Systems

Block and Tackle

A block and tackle is a compound pulley system where there are several fixed pulleys on one axis and several moveable pulleys on another axis [3]. The purpose of a block and tackle system is to drastically reduce the force required to move a load [3]. Boats use block and tackle pulley systems because they allow the sails to be easily adjusted, even in high wind, from a convenient location on the boat. In block and tackle systems the belts are made of rope.

Block and tackle used in a sailboat [7] |

Cone Pulley

A cone pulley is a fixed pulley where there are multiple grooves of different diameters on the same pulley [3]. The purpose of a cone pulley is to change the speed and torque of the output similar to changing gears on a bicycle [3]. Lathes use cone pulleys to adjust the speed of the spindle.

Cone pulley used in a lathe [8] |

Tensioner Pulleys

A tensioner pulley is a fixed pulley that is used to tension a belt. Tensioner pulleys are mounted to a spring load mechanism or adjustable pivot point that allow them to push on the belt to apply tension and prevent the belt from slipping. Tensioner pulleys are often used in systems that require precision or efficiency such as an engine timing belt. Having a good tensioner in an engine, is very important because if the timing belt loosens and the engine timing is off valves can contact the pistons and destroy the engine [9].

| Engine Accessory Belt Tensioner [10] |

Continuously Variable Transmission (CVT) Pulleys

A CVT uses 2 fixed pulleys with wedge edges for a v-belt. The v-belt is of a specific width so by moving the distance between the wedge faces of a pulley you can make the belt move up or down on the pulleys which changes the gear ratio. The pulleys must change oppositely to each other to keep the v-belt tensioned to the pulleys. The distance between the wedge pulley faces can be changed in very small increments which allows this pulley system to be continuously variable. CVT pulley systems are frequently used in cars because they allow the vehicle to accelerate while keeping the engine rpm low which is very fuel efficient [11].

| Side view of a CVT [11] | How CVTs change their gear ratio [11] |

How to Mount Pulleys to Shafts

Idler Pulleys

Idler pulleys are pulleys that will rotate independent of the rotation of the shaft. Idler pulleys typically use bearings the rotate independently of the shaft. There are 2 common ways of mounting idler pulleys. First, use a washer and bolt to hold the center of the bearing in place on a threaded standoff. This method is used to mount engine idler pulleys. Second, interference fit the bearing onto a shaft. This is usually done by heating the center of the bearing and/or cooling the shaft. Thermal expansion and/or contraction will allow the pulley bearing to fit over the shaft and once at room temperature the pulley bearing will be interference fit onto the shaft.

Fixed Pulleys

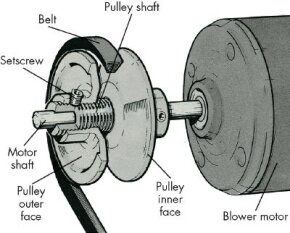

Fixed pulleys are pulleys that will rotate with the rotation of the shaft. There are 4 common ways of mounting fixed pulleys. First, use a key that goes into a keyway in the pulley and shaft. Second, use a set screw that threads into the pulley and contacts the shaft. If there is a flat section or divot on the shaft align the set screw to that as more of the surface of the set screw will contact the shaft and thus will keep the pulley from moving on the shaft at higher loads. Some pulleys have the option to use a key and a set screw. Third, use tapered bushings that go between the pulley and shaft. Tapered bushings make use of the wedge effect to convert the clamping force into radial pressure that locks the bushing to the pulley and shaft [12]. The wedge effect is described in the v-belt section of the Belts wiki page. Finally, interference fit the pulley onto a shaft. This is usually done by heating the pulley and/or cooling the shaft. Thermal expansion and/or contraction will allow the pulley to fit over the shaft and once at room temperature the pulley will be interference fit onto the shaft.

For more information on fits, see the Hole and Shaft Standard Fits wiki page and the Tolerance and Fits subsection of the Shafts wiki page.

| Fixed pulley mounted to shaft with key [12] | Fixed pulley mounted to shaft with set screw [13] |

Contributors:

| User | Last Update |

|---|---|

| Lesley Lang | 1270 days ago |

Faculty Advisor: Chris Rennick, Michael Lenover (Alumni)

.jpg?version=1&modificationDate=1611338118427&cacheVersion=1&api=v2&width=300&height=225)