Table of Contents

A Planetary Reduction Gearset in a Pratt and Whitney Turbine [1] |

|---|

Introduction to Gears

Gears transmit power between a pair of shafts and can be used to modify output speed and torque or change the direction of the input shaft. Metal gears are an excellent choice where precise movement, high power, and durability are concerned. For lower power applications or where noise is an issue, plastic gears can work well.

Many consumer goods contain gears. For example, a handheld mixer might contain a worm gear set to reduce the high speed of the universal motor to a few hundred RPM to spin the beaters. This reduction in speed conserves most of the power, so the torque of the beaters in increased. Gears are also critical components in automobiles, industrial machinery, and mechanical watches.

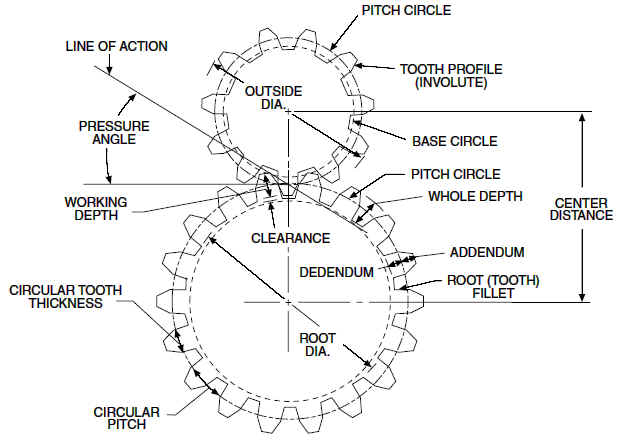

Gear Terminology

Spur gears are described by a number of dimensions in addition to the thickness of the gear. The most critical dimensions are the number of teeth and the center distance. These factors must be specified during the design process, even before a tooth profile is selected.

Gear Terminology [2] |

|---|

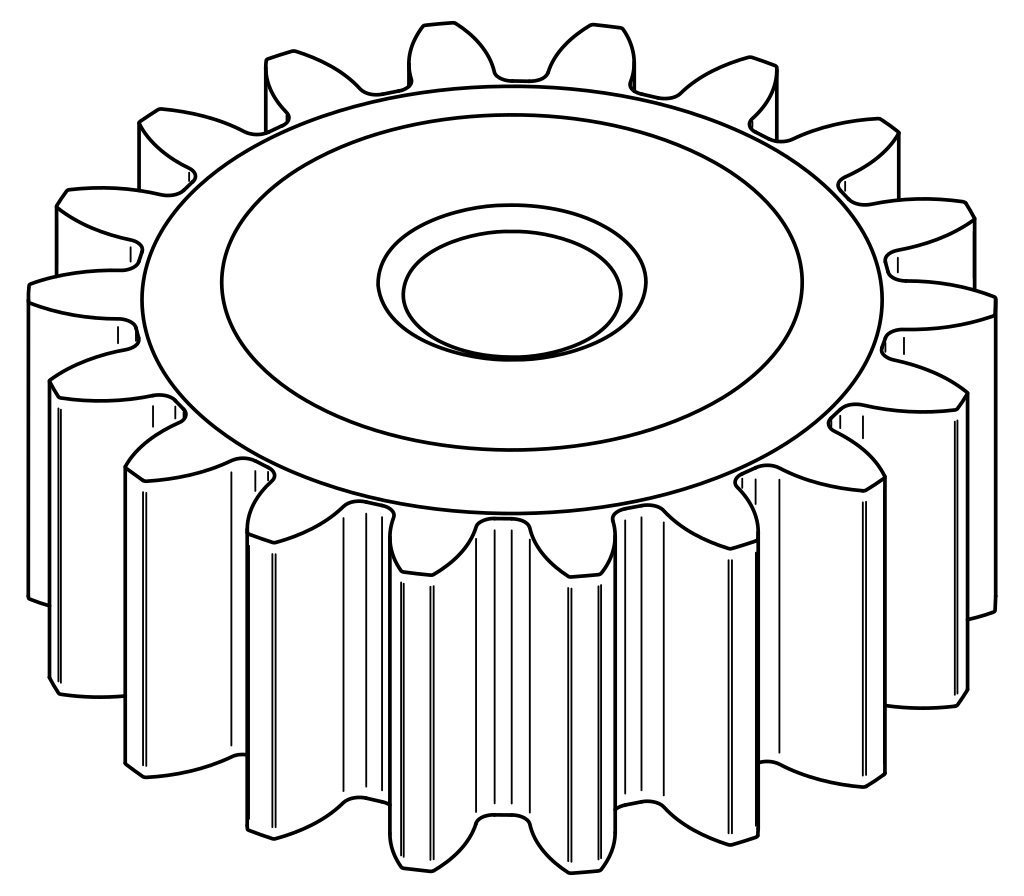

Spur Gears

A particularly common type of gear is the spur gear with an involute tooth profile, as shown to the right. The tooth form is perpendicular to gear face, meaning that all forces are in the plane of the gear. The involute tooth profile, generated by sweeping the perimeter of the base circle through the pressure angle. provides excellent meshing and wear characteristics.

Spur Gear [3] |

|---|

Helical Gears

Helical gears have many advantages over straight cut spur gears. They are quieter and have less backlash because the teeth make contact gradually along the profile. The input and output shafts can be parallel or at angles, as is the case with crossed helical gears. Helical gears produce an axial force along the shaft, requiring thrust bearings and gears designed to resist forces along the shaft axis.

Helical gears are also more difficult and expensive to manufacture, especially for workshops without special machine tools.

Helical Gears - Crossed and Helical [4] |

|---|

Double Helical (Herringbone)

Helical gears have many advantages, but their application is limited in some cases because they develop a force normal to the plane of the gear. Herringbone gears have two sets of opposing helical gears, meaning that all the out of plane forces are contained within the gear. If the two helical teeth meet at an edge, manufacturing may be complicated. This can be addressed by cutting a groove where the two teeth would meet. This allows space for a shaper cutter to run out into, instead of crashing into the second set of teeth.

Herringbone Gear Set - No Central Groove [5] |

|---|

Bevel Gears

Bevel gears have teeth projected along the outer surface of a cone. This sloped working surface allows the bevel gear to mesh with another bevel gear operating at an arbitrary angle. These gears are often used to transmit power between perpendicular, intersecting shafts. Bevel gears can be cut with straight teeth or helical teeth, depending on the design requirements.

Bevel Gears [6] |

|---|

Hypoid Gears

Hypoid gears are an excellent middle ground between a bevel or crown gear reduction and a worm reduction, with a wide range of reduction ratios available. The input shaft is set above or below the centreline of the output gear, unlike a typical bevel gearset with intersecting shafts. As the input shaft is brought farther and farther from the center of the output gear, the tooth angle, or pitch, of the input gear decreases, increasing the gear ratio. Unfortunately, this also increases the sliding action between the gears.

Hypoid Gears - Shaft Offset Below [7] |

|---|

Rack and Pinion

A rack and pinion allows the translation of rotational motion to linear motion. A rack can be though of as a truncation of a circular gear with infinite diameter. Therefore, the teeth have a pressure angle and are generated by the involute method, but the tooth profile is effectively straight. A pinion, often a spur gear with the same module as the rack, applies a force to the rack. A rack and pinion can also have helical teeth to achieve the same benefits as described above.

Rack and pinion gearing is an excellent choice when a component needs to be driven by a motor, but also moved by external forces. The low reduction and rolling action mean that a force acting on the rack can spin the motor, or transmit feedback back to a user moving a handle.

Rack and Pinion [8] |

|---|

Worm Gears

Worm gears are some of the most dense and simple ways to achieve high reduction ratios. A screw-shaped worm gear rotates past the wheel gear that has helical teeth cut into it. Since the output wheel moves by only one tooth for each rotation of the input worm, the reduction ratio can be very high. Worm gears are typically unable to be back-driven (where the output shaft is spun against the motor's driving torque) - the high reduction ratio and friction at the sliding interface lock the gear train. This characteristic is very useful for many machine designs. For example, a telescope positioning apparatus can be precisely aligned by turning the worm gear, but cannot be moved by bumping the telescope body, which is connected to the output shaft.

Worm Gear and Worm Wheel [9] |

|---|

Crown Gears

Crown gears have similar use cases to bevel gears, but use a normal spur gear on one of the shafts.

Crown Gears [10] |

|---|

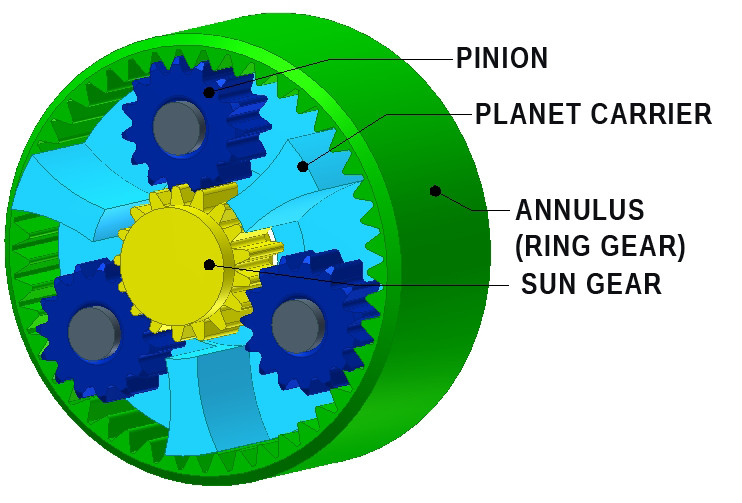

Epicyclic / Planetary Gearsets

Planetary Gearsets are an excellent choice to transfer torque from colinear input shafts. Multiple stages can be added to increase the reduction achieved.

Planetary Gearset [11] |

|---|

Gear Tooth Profiles

The tooth profile of a gear has a significant impact on the strength, Noise, Vibration, and Harshness (NVH). The earliest forms of gears used round pegs to transmit force from one gear to another. This is a simple, robust design, well suited to a flour mill or children's toy. Unfortunately, this design requires large clearances and has a large sliding action between the pegs. More advanced teeth, like involute and cycloidal profile teeth, use shapes which promote rolling instead of sliding. These shapes also allow the gears to precisely mesh together, eliminating backlash (free play) in the system.

Involute Gear Teeth

Involute tooth profile gears are by far the most common gears used today. The involute shape is formed by unrolling the perimeter of the base circle until the angle between a line connecting the starting point and the centre and a line connecting the end of the perimeter and the centre is equal to the pressure angle.

Involute Tooth Form |

Cycloidal Gear Teeth

Cycloidal gear teeth are a mostly obsolete tooth profile generated by the epicycloidal and hypocloidal path traced by a point on a circle rolling around two describing circles. The simplest case to understand is the path of a point on a generating circle of equal size to the pitch diameter [12]. These gears have low friction losses, but are very sensitive to changes in the gear depth [15].

Cycloidal Tooth Form [12] |

|---|

Triangular Gear Teeth

Triangular gear teeth are simple to cut with hand tools like a file, have geometry that is easy to draw, and are adequate for light loads and slow speeds. One major advantage of triangular teeth is that they can come into and out of mesh smoothly due to their straight sides and pointed form [15].

Triangular Tooth Form [13] |

|---|

Applications of Gearing, Gearboxes, and Splines

Automotive Manual Gearbox

One of the best known examples of gears is a manual gearbox in an automobile. It typically uses sets of helical gears running on a splined shaft. Each gear is engaged by a shifter fork, which is attached to the shift knob through a linkage. Sets of "dogs" or square posts on the face of the gear can engage a coupler with internal splines, allowing it to transmit power by the output shaft. Modern manual transmissions use a Synchromesh assembly to first match the speed of the coupler with the driving gear.

Automotive Automatic Gearbox

Automatic gearboxes are now very common on new cars- they are easy to use and can be very efficient if controlled by the vehicle Engine Control Unit (ECU)

Industrial Gearsets

Industrial gearboxes are used to transmit power while altering the speed or direction of the output. The design requirements are often less strict than marine or automotive gearboxes as pitch-line speeds are lower and weight is less of a factor for stationary gearboxes. (designbasicind, p6). Various requirements, like the ratio of input and output speeds, influence a designer's choice of gear reduction.

Contributors:

| User | Last Update |

|---|---|

| Lesley Lang | 1118 days ago |

| Former user (Deleted) | |

| Former user (Deleted) | |

| Former user (Deleted) |