...

| Team | Year | SAR Score | Extreme Retrival Score | Equipment Servicing Mission | Picture | Number of Fingers in gripper | DOF in end effector | Allen Key feature | Other comments |

|---|---|---|---|---|---|---|---|---|---|

Ryerson Rams Robotics | 2019 | 90 | 77 | 4 | 1 | Not apparent | 4 fingers make it easy to grab rocks They are lacking strength in the wrist | ||

| IMPULS | 2019 | 80 | 69 | 2 | 1 | Not apparent | Very rigid stiff | ||

| PCz Rover Team | 2019 | 80 | 42 | 2 | 1 | Not apparent | Interchangeable end nubs | ||

| Stanford Student Robotics | 2019 | 64 | 57 | 2 | 1 | Not apparent | rubber band in v grove for compliance. | ||

| Michigan Mars Rover Team | 2019 | 32 | 54.5 | 2 - one fixed | 1 | Not apparent | no compliance? - didn't score well for extreme retrieval. perhaps it is correlated Arm is very interesting, no fancy links just direct drive through a gearbox. Not very aesthetic though. | ||

| Michigan Mars Rover Team | 2020 | 96 | 2 | 2 | Allen key has its own lead screw on the outside of the claw. Might be off center of rotation | No slip ring wires allow a certain number of twists Wire management is also kinda a mess on this bot. | |||

| Stanford Student Robotics | 2020 | 94 | 2 | 1 | Allen key coupled with the central lead screw that controls the jaws | Wrist looks like it has no slip ring. Jaws fold back, exposing the allen key, and the axis 6 screws in the screw. Looks like a coaxial axle is used to control both axis 6 and the jaws. They have a very good design. | |||

| BRACU University Mongol-Tori | 2020 | 93 | 2 shovels | 1 | Not apparent | Chain driven axis 6 is interesting. piston rod driven gripper is also interesting. Allows for axis six to 'wrap around' it without any issues. A sort of mechanical slip ring. | |||

| Missouri S&T Mars Rover Design team | 2020 | 93 | 2 spring loaded | 1 | Opposite side of the differential. Looks like it has multiple tooling bits! | gripper looks like it only half works, as one complies fully and the other does not. 2 cameras for each tool which doubles the expense there. Nice small cameras though. | |||

| Mars Rover Manipal | 2020 | 92 | 2 | 2 | Differential wrist with isolated Allen key with its own motor. | Very simple and cheap good design. Very epic CAD render transitions | |||

| Team Anveshak | 2020 | 91 | 2 | 2 | Allen Key is 90° from the claw and has its own motor | A nice compliant mechanism Very good claw. Love the Erasers. |

Additional Notes:

From other teams it seems strength of gripper is the biggest contributor to performance. the great variation in grippers also suggests also that the performance in each mission is heavily dependent on the performance of the arm and control system. This can be seen from IMPULS' very simple digit claw that has no compliance. compared to Michigan though, they have a cup shape grove which may help slightly

A lot of good teams, also have solenoids to trigger keyboard keys. this way the alignment can be done before hand without relying on dynamic precision.

Also note that no one uses slip rings! Also note that no one uses coaxial transmission shafts. It might be too difficult to design/too difficult to manufacture or just decided to go direct with the motor. None of these designs look very aesthetic, except for maybe Stanford, but that's my opinion.

End Effector

This is the claw, tool bit and key stroke pusher rolled into one. It is used to grip items in retrieval missions, turn cap screws with a hex drive feature, and push keys on a keyboard. Previously, our team has used an square end Allen key to turn the cap screw as well as push the keys. Some teams use a solenoid to push keys.

...

Human skin is around 10A, foot insole gel is around 30A, car tire is around 50A. Bars of urethane rubber can be found on McMaster-Carr for a good price, the softest material being ~40A but we can fabricate our own using silicon if need be. These Rubber bars can be cut with a water-jet but tolerancing might be iffy. 3D printing is also an option. 3D printing can be comparable in price or more expensive, whilst giving unique challenged that take a lot of time to tune. this is not something I am particularly interested or knowledgeable about so if anyone has any words on the subject please feel free to comment.

...

This looks like it is rubber dipped 3d printed plastic, very interesting concept from Binghamton University

Tool Torque

Tighten captive screw to secure drawer. Screw will be a 5/16”Allen (hex)head.

Assuming elbow rotates*

A 5/16" Allen key is used to drive a 3/8" socket head screw. A 3/8" UNF socket head screw requires 26 ft lbs. (35.25 Nm). This is more torque than required for the forearm to hold a 5kg at 90° (including wrist weight) extended 25 cm out accelerating upwards at 1G.

this is worst case scenario below.

< crude calculations

Gripper torque

https://www.redwoodplastics.com/wp-content/uploads/2019/03/Urethane-2019.pdf

This is very encouraging, but for the sake of calculation we will assume a coefficient of friction, between the contact pads and what we are gripping as 0.65, as sources very. It will also be assumed we have a bad grip on the object (IE without friction the part would slip out, not cupped)

Mechanical geometry

This pertains to the 2 finger end effectors.

This is what I define as the path the jaws take during the open close cycle. There are several different types used in competition. Each with subtle advantages and disadvantages relating to the effectiveness, ease of design, cost of design and number of parts.

some aditional notes can be found here: https://en.wikipedia.org/wiki/Four-bar_linkage

| Linkage Type | Image | Notes | Jaw Parallelism |

|---|---|---|---|

| Geared Parollelogram linkage | This is what we have (instead of gears it is leadscrew) note the outward extension of the tips vary during the stroke | Jaws Stay Parallel | |

| Central Piston | This could be a lead screw or other Nice because it is symmetrical Also nice because it is gearless This could be mixed with the parallelogram | Positive angular separation at open | |

| Linear Slide | No outward extension during stroke May increase the cost due to the need of linear slides | Jaws Stay Parallel |

More possible actuator types

...

These pads bay be feasible to create with a fresnel lense as a mold and silicone as the gripper material which can be stuck on the existing gripper. Thought emporium has a well documented video on this. Many use this with soft robots, but this can also be used as a 'glove' on the existing claw.

Note to self look into what other teams did for allen key

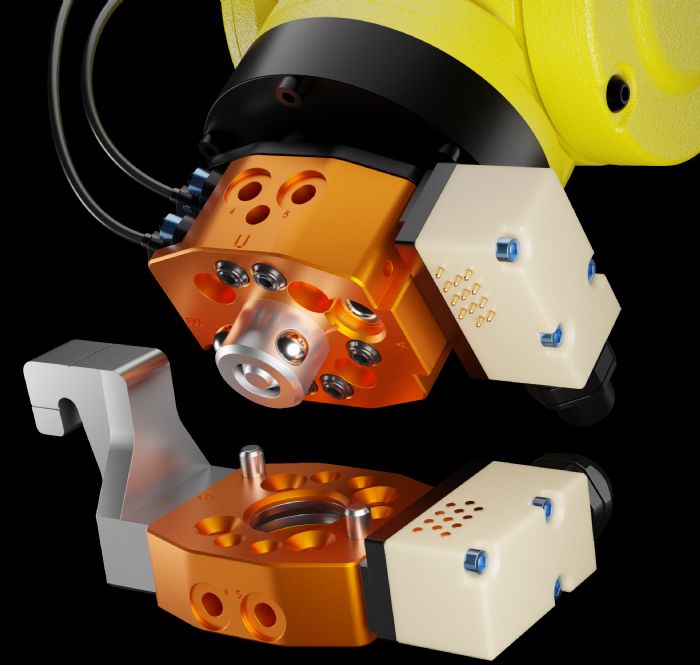

Tool changing.

This could be if we have mutiple different grippers, or a gripper and a allen key, or a hook, etc.

+ It would decrease the complexity of the singular end effector

- increase the complexity of the wrist mount point.

- Have to worry about clean contacts (if the end effector was electrically controlled)

+ Great opportunity to learn

+ Lighter arm

- Heavier overall mechanism