Table of Contents

Table of Contents

What are Mixers

Mixers are vessels with perform the act of mixing. Mixing can be defined as the process of combining two heterogeneous materials into one homogenous product. This can be done in either a batch or continuous process (see Reactors). Batch mixers are usually used for smaller scale productions, and continuous mixers are normally used for larger-scale industrial applications [1].

Design Considerations

Some aspects to consider while choosing a mixer are the type of mixing which must be achieved (see below), the mixing temperature and possible need of a coolant system, and the presence of a catalyst.

Types of Mixing

There are 6 types of mixing, which are the different mixing type between the three states of matter, solid, liquid, and gas. The type of mixing determines the design requirements for the mixer and the type of mixer that needs to be used. Additionally, these can be split up into static and non-static power mixing.

Static Mixing

Static mixing is the process of mixing fluids using a specialized Static mixer, which does require any power or moving parts, but relies solely on the geometry of the mixer, and the properties of fluids such as gasses and liquids [2]. This process is only used for these three types of mixing, as any solid material can clog the mixer. However, these mixing methods are not necessarily required to use a static mixer, as some older methods still use non-static mixing power mixing methods.

| Image of a Helical Static Mixer [3] |

|---|

Liquid-liquid mixing

Liquid-liquid mixing is one of the most common forms of mixing, and can be found used in all places from local bakeries to oil and gas refineries. A common liquid-liquid mixer is an agitator inside of some kind of tank [1], or a helical static mixer.

| An example of an Agitator | ininside of a Tank |

|---|---|

Gas-gas mixing

Gas-gas mixing is a very simple to perform process, as gases mix very easily together, and can usually just be combined in a vessel together, such as a pipe or tank.

| Diagram of a Gas Mixer [5] |

|---|

Liquid-gas mixing

Liquid-gas mixing is usually the process of dissolving a gas into a liquid. An example of this is the carbonation of a soft-drink.

Power Mixing

These mixing methods remethods are methods which cannot be accomplished without any added force or moving pieces.

Solid-solid mixing

Solid-solid mixing is usually achieved by kneading the two solids together, usually in a dust or paste form.

| Example of a Kneader [1] |

|---|

Liquid-solid mixing

Liquid-solid mixing has the goal of suspending the solid in the liquid. An example of this is concrete, which is a mixture of sand, small rocks, water, and cement.

| Example of an Extruder [1] |

|---|

Solid-gas mixing

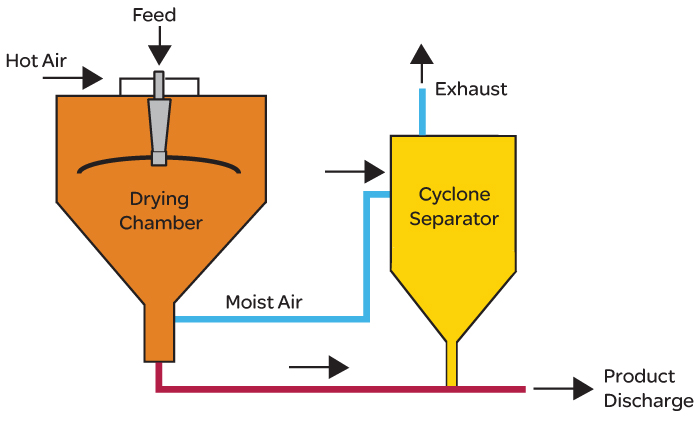

Solid-gas mixing can be used in various use cases, or can sometimes be a side effect of other processes, such as a solid catalyst interacting with a gas. Dryers, namely Direct Drying, which suspends tiny particles of dirt in the air stream during the drying process. The dirt particles are then removed using cyclone.

| Diagram of a Direct Dryer and a Cyclone Separator [6] |