Table of Contents

Overview

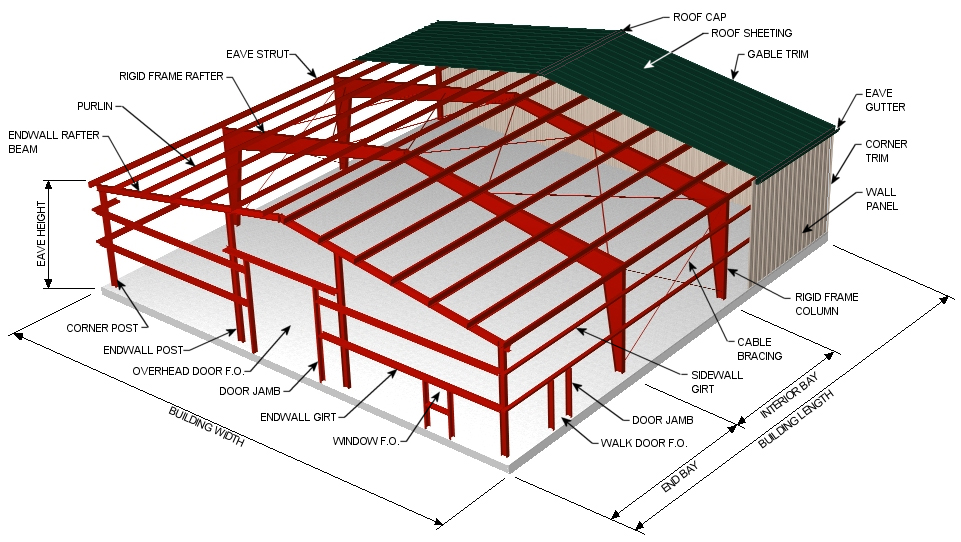

An exterior wall assembly consists of a system of components that supports and functions as a building envelope. They are designed primarily to protect the interior side from the conditions exposed to the exterior side. However, as time progresses and technology evolves, the functions of a wall assembly subsequently evolve. Additional individual functions include fire-resistance, sound-proofing, blast resistance, water-proofing, and more. Individual wall assemblies have their own set of components and standards, depending on their intended functions.

It is important to consider the environment around the wall, and what kind of performance you are willing to obtain from a wall assembly. That is ultimately the deciding factor for many of these materials for performance. There are also restrictions based on what's readily available to purchase in any geographical location since prices can fluctuate greatly.

| Figure: 1 Labelled Wall Assembly [1] |

|---|

Components

Individual wall assemblies have their own set of components and standards. There are instances where materials will be multipurpose to improve the walls operation. However, most share a set of common components, as listed below from exterior to interior [1].

Exterior Cladding

Exterior cladding is the primary barrier to prevent moisture entrance into the interior side, it is very commonly also referred to as "Siding". Typical materials include stucco, exterior insulation finishing system, clay brick, vinyl siding and cedar siding. To decide between which exterior cladding is used, a number of reasonable considerations are made. Notably, exterior cladding is the part of the wall that is seen by the outside world so material is typically chosen to look good as well as being functional.

Exterior Sheathing Membrane

The exterior sheathing membrane is the waterproofing layer that protects the underlying structure from moisture insertion. Asphalt impregnated Kraft paper (also known as building wrap) is a typical exterior sheathing membrane material used for residential buildings. Commercial buildings rely on more modernized waterproofing systems (e.g. self-adhering styrene-butadiene-styrene (SBS) rubberized asphalt sheets).

Exterior Sheathing

Exterior sheathing is the flat surface that receives the exterior sheathing membrane around the perimeter of the building. It is typically made up of manufactured wood products such as plywood or oriented strand board (OSB).

Insulation

Insulation consists of material used within the wall assembly to diminish the transfer of heat passing through. The insulation is usually placed in the gap space between structural components. Common materials include fiberglass batts, polyisocyanurate rigid board, and polyurethane foam. The materials differ in application, thickness, and density to provide different levels of insulation at different sizes.

Fiberglass is very common due to its mass production, price point and effectivity. It can come in a few different forms. Either batts, rolls or loose fill. They are each fairly similar in effectiveness and are independently chosen for the purpose of application. Batts are pieces of blanket insulation that are pre-cut to manageable sizes, while rolls are similarly pre cut but much longer. These are useful when filling in-between studs which are typically of predetermined size. These can come faced or unfaced. Facing is used to retard vapour, which provides the insulation with another layer of protection from exterior elements.

Unfaced fiberglass insulation (https://andersoninsulationme.com/fiberglass-insulation-facts/) | Faced fiberglass insulation |

|---|---|

Loose fill is small clumps of fiberglass. Application of this is typically through a tube that sprays it out quickly. You find this kind of insulation on flat surfaces, like an attic as the clumps sit onto a surface and would be ineffective in remaining standing within a wall like batts or rolls would.

Loose fill insulation being applied |

|---|

A polyisocyanurate rigid board is useful in it's own way as well. It provides very good insulation more so than fiberglass per inch due to its density. This being the case, it is not used in the same quantity, it is instead used for tight spaces, when there is less space available for insulation or for the sake of space savings. They come in precut rigid boards, as they cannot be rolled, and thus are put onto flat surfaces. The rigidity also provides structural support. A common way this insulation is applied is with adhesive glue. Since it has strong adhesive properties and is light in weight, it is common to place on surfaces such as ceilings or walls angled downwards.

Polyisocyanurate rigid board on an angled ceiling https://www.homeconstructionimprovement.com/insulating-cathedral-ceiling-with-foam-board/ |

|---|

Structural Components

Structural components encompass a wide variety of components used to transfer and bear load for a wall. Wood studs are the primary structural components for residential buildings, whereas industrial/commercial buildings are supported by components such as cold-formed steel studs, reinforced concrete, mass masonry, and structural steel members. Steel studs typically consisted of a track which would allow for wires and pipes to easily run throughout the wall. There is a wide variety of

Steel Studded Wall (https://www.jlconline.com/products-tools/kitchen/mounting-a-wall-hung-sink-on-a-steel-stud-wall_o) | Mass Masonry Wall | Structural Steel Members |

|---|---|---|

Air and Vapour Barrier

The air/vapour barrier manages and controls the mass transfer of air or water through the wall assembly. Unwanted fluids passing into the assembly can result in loss of heat retention or mold build-up, and can deteriorate structural integrity as well. Separate air and vapour barriers are commonly installed in placed of high humidity, the locations of which depend on the exterior climate and interior use. Typical residential wall assemblies use polyethylene sheets as the primary air/vapour barrier. These barriers can be a part of the insulation, called "faced insulation" or it can be put on independently.

Air and vapour barriers differ in function slightly. Air barriers main purpose is to stop air from flowing into the structure. A difference of air pressure of the interior of a structure and outside of a structure can cause this to happen. This stops moisture trapped in the air (humidity) from entering the structure. Vapour barriers stop moisture from diffusing into a structure. A vapour barrier stops moisture from seeping in. There are types of barriers that provide both types of protection.

Interior Sheathing (Drywall)

Interior sheathing is the interior surface of the wall assembly that the occupants will interact with. The most common material is gypsum board, also known as drywall, as it is a very smooth surface. OSB (plywood) is also used as a cheaper alternative but is typically not as aesthetically pleasing, even with multiple layers of paint the texture can still be seen.

Common Types

There are many different types of wall assemblies, as the application for these assemblies differs wildly depending on factors including building type (e.g. residential vs commercial) or climate. Listed below are a few common wall types and their uses.

| Type | Description | Visual | ||

|---|---|---|---|---|

Cavity Wall | Cavity walls are double walls consisting of two wythes, vertical layers also known as leaves, of masonry. The two walls are separated by an air space and joined together by metal ties. They are often used in colder climates, as they have a heat-flow rate that is 50 percent of that of a solid wall. These walls can be load bearing or non load bearing. A drainage cavity (air space) collects excess moisture that passes through the exterior cladding element and is then re-directed to the building exterior with the help of cavity flashings (waterproof sheets) [2]. |

| ||

Mass Wall | Mass walls take a different approach to water drainage compared to cavity walls. This approach involves using sufficient mass and thickness, so the wall can absorb any water that is not deflected or drained away. It is also known as the storage wall, as it will hold the water until evaporation occurs. They are typically made of concrete block, concrete, insulated concrete form, masonry cavity, brick, earth, adobe and solid timber or logs [3]. |

| ||

Load-Bearing Wall | A load-bearing wall consists of sturdy, durable materials such as thick wooden beams, concrete, brick, or steel. It is primarily designed to hold up the weight of the building above it by distributing the weight down to the foundation. Retaining walls, also considered load-bearing walls, provide lateral support for a building [4]. Load bearing walls are not always the exterior wall. |

| ||

Non-Load Bearing Wall | Non-load bearing walls do not provide structural support. They are used to divide an area into smaller portions, commonly referred to as partitions or curtain walls. As they are not integral to the structure, they are common made of less dense materials. They often include two-by-fours and sheetrock, with insulation in between. Common materials include terracotta, hollow bricks, façade bricks, steel panels, wood, or sheet glass [4]. |

|

Contributors:

| User | Last Update |

|---|---|

| Former user (Deleted) | 1221 days ago |

| Former user (Deleted) | 1304 days ago |

| Former user (Deleted) | 1305 days ago |