Table of Contents

What is Power Transmission?

Mechanical power transmission refers to the transfer of energy from a generation source to the location where useful work using simple machines, linkages, and mechanical power transmission elements is performed. Many machines contain some system of power/motion transmission that operate with a provided input (fuel) [1]. Power transmission systems provide speed, torque, and/or direction of rotation conversion from a power source to another device [2]. The importance of power transmission is the ability to transfer energy and provide work in different amounts of space with some cost to efficiency. It can also be noted that power transmission systems can alter the work output (think changes in rotation speed and torque) [1].

Mechanical power transmission elements can be classified into numerous types which include: shaft couplings, power screws, gears and gear trains, brakes and clutches, belts and pulleys, and chains and sprockets [1]. These elements can be seen everywhere, from industrial applications to day to day life. One of the most common examples would be in an automobile, where the wheels are propelled by the engine [2]. The mechanical power generated by the engine is transferred to the wheels through a transmission system. Bicycles are also a very common example of the application of a mechanical power transmission system. A common industrial example would be a conveyor belt.

Power Transmission Components

Types of Gears

Types of Belts

Types of Pulleys

Types of Shafts

Types of Bearings

Power Transmission Systems

Gear Drives

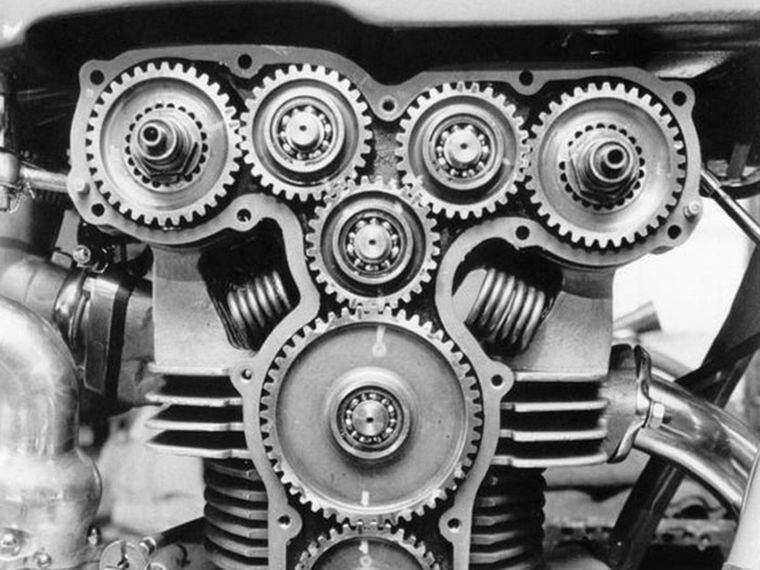

Gear drives are the most widespread form of mechanical transmission [4]. Gear drives are defined as the transmission of motion or torque from one shaft to another by means of direct contact between toothed wheels (gears) [5]. Gear drives boast a number of advantages and disadvantages. The main advantages of gear drives are: their compact structure, which makes them suitable for short range transmission; high efficiency, as well lubricated drives only have an efficiency loss of 1-2 percent; lack of slippage; and a high reliability and long life [5]. The shortcomings of gear drives are that they are not suitable for transmission between two axes at a long distance. Furthermore, they require a high level of precision in manufacture and installation, resulting in higher costs. It should be noted that gear drives are incredibly versatile, as they can be found in, both, small scale and large scale applications.

Torque (τ) and rotational speed (ω) are inversely proportional due to the relation of P=τω. So when rotational speed decreases, the output torque increases and vice versa. In a gear drive, the transmission of power through the gears will change with the gear ratios. This ratio is the ratio of the pitch diameter, the circle from where the teeth of a gear makes contact with other teeth [12]. Gearing down means transmitting power from a larger gear to a smaller gear reduces speed and increases torque, gearing up does the opposite. Since motors are fast by nature, most applications will gear down. Gear drive efficiency varies from different gear shapes and the relative sizes of two mating gears as well as tooth shape and contact angle [12]. Consideration is necessary when designing a gear drive. Stress calculations to determine the right gear size, width and the right tooth size will be required to ensure an appropriate lifetime.

An example of a gear drive found in a motorcycle engine [6]. |

|---|

Belt Drives

Belt drives are a form of mechanical transmission which utilizes a flexible belt that is tensioned on a pulley for motion or power transmission [4]. Belts are a simple, effective and cheap way of transmitting power but is a less efficient than other common power transmission devices. The flexibility of the belt gives the system some tolerance to impact and vibration which can help prevent damage. If there is an overload, the belt can slip off to avoid breaking the machine. The belt is a very versatile way of routing power between two points with tensioning necessary at the input and output pulleys. This is often achieved by having one of the pulleys on a slot or some tightening mechanism so it can pull the belt taut into position. In many custom use cases, using common sizes found on the market might not be taut without designing a potential inefficient route for the belt. Instead, using tensioning guide wheels can get a taut fit to taut transfer power. Since the belt is not perfectly fixed and can vary in tension and in slip conditions, it is not guaranteed to get a fixed gear ratio. This inaccuracy makes the belt drive more inefficient and the diameter ratio is often larger (than a gear drive), resulting in a larger outer dimension. Belts have a relatively short service life compared to other transmission systems due to the wear and tear on the softer belt material.

A very common application of belt drives can be seen in washing machines as well as drill presses. In the workshop, many drill presses vary speed by opening up the drill press and moving the belt between different sizes of pulleys.

| An example of a belt drive found within a washing machine [7]. |

|---|

Chain Drives

Chain drives are a form of mechanical power transmission that are widely used in cases where shafts are separated at distances greater than that for which gears are practical [7]. Chain drives boast a number of advantages and disadvantages. The main advantages of chain drives are that: unlike belt drives, they are not prone to slippage; they can be up to 97% percent efficient; they can function in harsh environments, and even in wet conditions; the required tension of the chain is small; and there is a lower load on shafts compared to belt drives [8]. The main disadvantages of chain drives are that: they can only be used for transmission between two parallel shafts; installation and production is more expensive compared to belt drives; they require regular lubrication; they are not suitable for applications where its necessary for the drive to slip; and they are also noisy and can cause vibrations [9].

Diagram of a chain drive found in a bicycle [3]. |

|---|

Shaft Drives

Shaft drives are a form of mechanical power transmission that uses a drive shaft, which is a mechanical component which is primarily used to transfer torque between components separated by a distance [10]. Shaft drives boast a number of advantages and disadvantages. The main advantages of shaft drives are: their longevity, as they are durable; low maintenance and upkeep; compactness, as bevel gears and drive shaft take up less volume than an enclosed chain; less likely to jam; and very consistent performance. The main disadvantages of shaft drives are that: they are not as efficient as some other systems of transmission, as they can be up to only 95% efficient; they weight a bit more than a chain drive; and due to their relative complexity of design, shaft drives are relatively more expensive than alternate forms of transmission.

Example of a shaft driven bicycle [11]. |

|---|

Contributors:

| User | Last Update |

|---|---|

| Former user (Deleted) | 1197 days ago |

| Former user (Deleted) | 1267 days ago |

| Former user (Deleted) | 1269 days ago |

| Former user (Deleted) | 1269 days ago |

| Former user (Deleted) | 1315 days ago |

Faculty Advisor: Chris Rennick and Michael Lenover (alumni)