Table of Contents

What are Pumps?

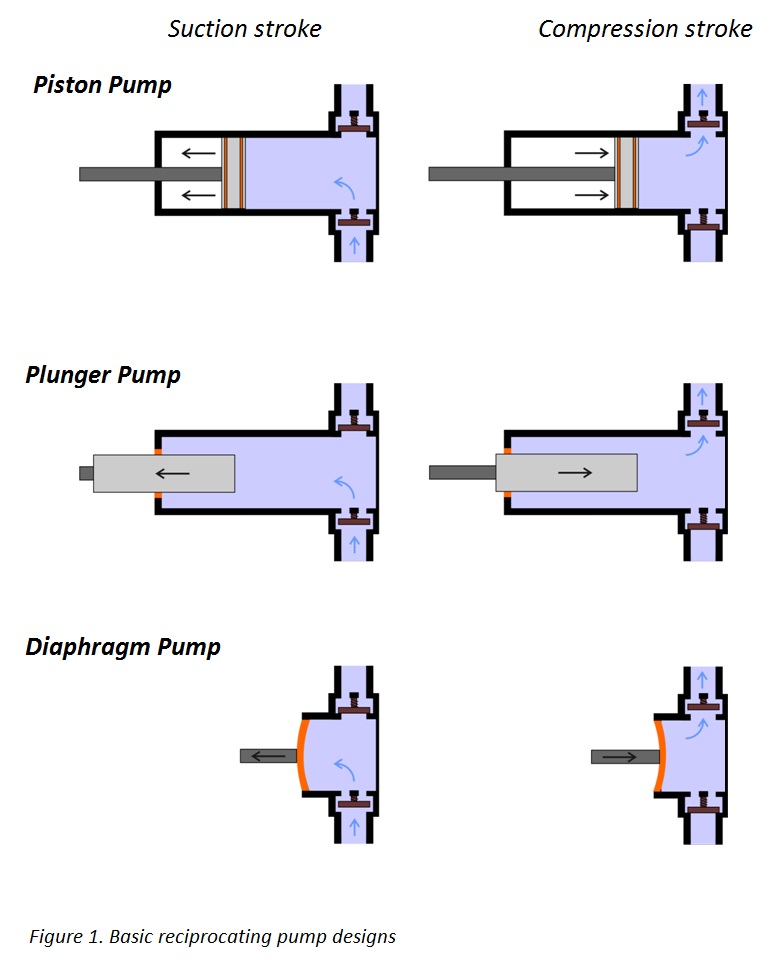

Pumps are devices that are focused on the movements of fluid (gases or liquids). Pumps can come in many different sizes and specifications, ranging in purpose and scale from near microscopic pumps that move extremely precise amounts of fluids, to large industrial pumps that transfer massive amounts of fluids every second [1]. Pumps typically have a reciprocating or rotary mechanism that performs the mechanical work on the fluids to move them [1].

Positive-Displacement and Nonpositive-Displacement

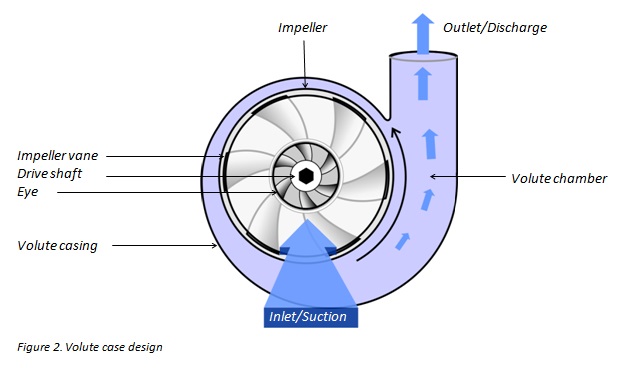

There are two main categories for pumps, positive-displacement and nonpositive-displacement, that share some common traits while having unique methods [1]. While the primary focus of both types of pumps is to transfer fluids to a desired location, they operate under very different principles and mechanics. Positive-displacement pumps move the fluids by repeatedly enclosing a fixed volume and then mechanically moving that volume through the system and out the output valves [2]. Nonpositive-displacement pumps work by adding kinetic energy to the fluid, thereby increasing the fluid's velocity and moving the fluid through the pump [3]. Because of these different mechanisms for moving the fluids, the pumps work most effectively under different sets of conditions, the following table highlights some of the most significant differences in pumps and may help in choosing the appropriate type for a given application [3].

Key Differences in Positive-displacement and Nonpositive-displacement Pumps [3]

| Characteristic | Positive-displacement pumps | Nonpositive-displacement pumps |

|---|---|---|

| Pressure | Work in high pressure applications, up to 800 bar (80,000 kPa) | Used for low pressure applications, maximum pressure of 18 to 20 bar (1,800 to 2,000 kPa) |

| Efficiency | Efficiency increases with increasing pressure | Efficiency peaks at best-efficient-point. At higher or lower pressures, efficiency decreases |

| Viscosity | Efficiency increases with increasing viscosity | Efficiency decreases with increasing viscosity due to frictional losses inside the pump |

| Performance | Flow is constant with changing pressure | Flow varies with changing pressure |

Examples of positive-displacement pumps [2] | A type of nonpositive-displacement pump, known as a centrifugal pump [2] |

|---|---|

References

Contributors:

| User | Last Update |

|---|---|

| Former user (Deleted) | 1253 days ago |

| Former user (Deleted) | 1254 days ago |

| Former user (Deleted) | 1254 days ago |